Top Flap Discs and Cut-Off Wheels for Metalworking

Abana Chapter

February 09, 2024

Navigating the world of metalworking tools can often feel overwhelming, but understanding the essentials of top flap discs and cut-off wheels is a game-changer for enthusiasts and professionals alike. This guide dives deep into the nuanced differences between aluminum oxide, ceramic, and Zirconia Alumina discs, tailored for various metals and tasks, ensuring you select the right abrasive for your project. With insights on securing free shipping, leveraging discounts on your first order, and prioritizing safety, we're here to streamline your purchasing process and enhance your metalworking efficiency.

Key Takeaways

Understanding the differences between aluminum oxide, ceramic, and Zirconia Alumina discs is crucial for selecting the right abrasive for your metalworking project.

Flap discs offer versatility and can be tailored for various metals and tasks, enhancing efficiency and outcome quality.

Cut-off wheels are designed for precision and durability, making them essential tools for specific metal cutting operations.

It's important to recognize when to use flap discs versus cut-off wheels based on the specific requirements of your metalworking project.

Leveraging offers such as free shipping and first-order discounts can significantly reduce the cost of acquiring metalworking discs and wheels.

Prioritizing safety when using flap discs and cut-off wheels is paramount to prevent accidents and ensure a smooth metalworking process.

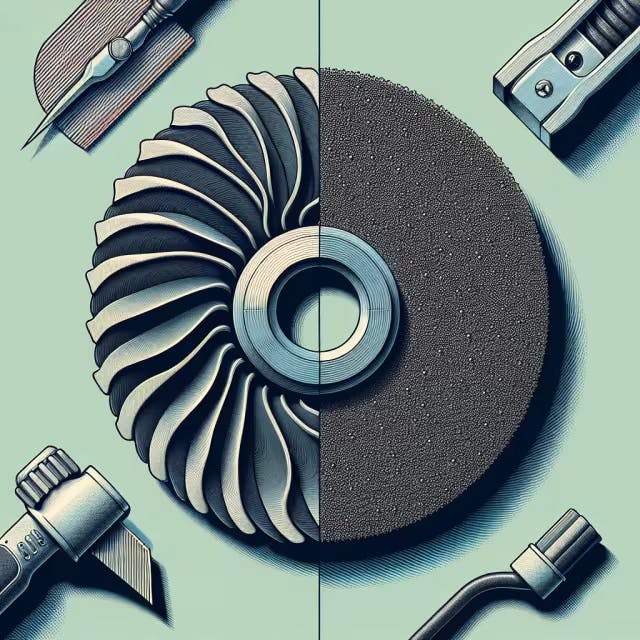

The Essential Guide to Flap Discs for Metalworking

Choosing the right flap discs and cut-off wheels is crucial for efficient and effective metalworking. The market offers a variety of options tailored to different materials and applications, making the selection process a bit overwhelming. Here are highlights of top choices, designed to help you find the best solutions for your metalworking projects.

Zirconia Alumina Flap Discs: Ideal for heavy material removal on steel and stainless steel. Zirconia alumina is durable and maintains its sharpness, providing a consistent finish over time.

Ceramic Flap Discs: These discs are perfect for precision work on stainless steel and other heat-sensitive materials. Ceramic grains offer cooler cutting and faster material removal rates, with minimal risk of discoloration.

Aluminum Oxide Flap Discs: Best suited for general-purpose metalworking, including rust removal and deburring on softer metals like aluminum. While not as durable as zirconia or ceramic, they are cost-effective for light-duty applications.

Silicon Carbide Flap Discs: Known for their sharp cutting ability, these discs are excellent for working on materials like glass, stone, and plastic in addition to metal. They are particularly effective for applications requiring a fine finish.

Cut-Off Wheels: When it comes to making clean cuts in metal, selecting the right cut-off wheels is paramount. Look for wheels that offer a balance between cutting speed and durability. Abrasive options like aluminum oxide for ferrous metals and silicon carbide for non-ferrous materials can match your specific needs.

Personalized approach in selection is key, considering the type of metal, desired finish, and working speed. Investing in quality products not only ensures better outcomes but also enhances safety during operations. Review trusted brands and seek out products that align with your work requirements for an optimized metalworking process. For detailed product reviews and recommendations, visiting industry-leading websites can be incredibly helpful, offering insights from professionals and users alike.

Best Cut-Off Wheels for Precision and Durability

For metalworking projects that demand both precision and durability, selecting the right cut-off wheels is crucial. Recent reviews and product tests have highlighted industry favorites, emphasizing their performance and reliability. Here is a brief overview:

DeWALT Cutting Wheels: Known for their fast cutting speed and long life, these wheels stand out in performance tests. They are compatible with various metals, making them versatile for different projects.

Makita Cut-Off Wheels: They offer an impressive balance of cutting efficiency and durability. The consistency in their performance has made them a favorite among professionals.

3M High Performance Cut-Off Wheels: With their advanced abrasive technology, these wheels provide smooth, fast cuts and are highly durable. Ideal for precision work, they help reduce the need for secondary finishing.

In the realm of metalworking, where accuracy meets tough materials, these top choices in cut-off wheels ensure your projects are not only completed efficiently but also with the desired finish. For detailed comparisons and user feedback, visiting manufacturer websites and dedicated tool review platforms is advised. This will help you make an informed decision tailored to your specific metalworking needs and preferences.

Flap Discs vs. Cut-Off Wheels: Understanding the Differences

When choosing between flap discs and cut-off wheels for metalworking, it's vital to understand their specific functions to select the most suitable tool for your project. Flap discs are primarily used for precision grinding and finishing, offering a blend of aggressive removal and a smooth finish, making them ideal for metal fabrication and auto body work. Cut-off wheels, on the other hand, are designed for cutting through metal, offering quick, clean cuts but without the finishing capabilities of flap discs.

Feature | Flap Discs | Cut-Off Wheels |

Primary Use | Grinding and finishing | Cutting |

Application | Metal fabrication, auto body | Metal cutting operations |

Finish | Smooth | N/A |

Material | Coated abrasives | Bonded abrasives |

It's clear each tool serves a distinct purpose in the metalworking process. For detailed grinding and achieving a refined finish, flap discs are your go-to option. However, for efficiently slicing through metal, you'll want to opt for cut-off wheels. By understanding these differences, you can ensure you're not only working efficiently but also achieving the desired results on your metalworking projects.

Maximizing Efficiency with Top Metalworking Discs and Wheels

Selecting the right flap discs and cut-off wheels is pivotal for achieving precision and efficiency in metalworking projects. These tools significantly influence the quality of the finish, the speed of operation, and the overall productivity in workshops.

Flap Discs: Ideal for grinding, blending, and finishing on a variety of metals, flap discs offer versatility and longevity. Their layered abrasive flaps adapt to the workpiece, providing a smoother finish than traditional grinding wheels.

Cut-Off Wheels: These are essential for cutting metal, including steel and stainless steel, with precision and speed. They're designed to handle high-pressure situations, making them suitable for demanding cutting tasks.

When choosing flap discs, consider the grit size and type; coarse grits remove material faster, while finer grits are for finishing. Similarly, the composition of cut-off wheels affects their cutting ability and durability. Here's a quick guide to help you choose:

Feature | Flap Discs | Cut-Off Wheels |

Material Type | Zirconia, Ceramic | Aluminum Oxide |

Grit Size | 40 (Coarse) - 120 (Fine) | N/A |

Durability | High with proper use | Very High |

Best For | Grinding & Finishing | Precision Cutting |

For detailed information on specific products that have been rated highly by professionals, consult trusted sources and reviews. Making an informed decision will not only ensure quality results but also enhance safety and efficiency in your metalworking tasks.

Selecting the Right Abrasive for Your Metalworking Project

Choosing the best abrasive tools is a crucial step in any metalworking project. The performance of flap discs and cut-off wheels can significantly affect the final outcome. Here's a concise guide to help you navigate the options and find the top products for your needs.

Flap Discs: Ideal for finishing and polishing, flap discs blend grinding and sanding capabilities into one tool. Look for ones made from zirconia alumina for general use or ceramic alumina for tougher materials and longer life.

Cut-Off Wheels: These are essential for cutting through metal quickly and cleanly. Opt for thin wheels for precise cuts and thicker ones for more robust applications. Abrasive materials like aluminum oxide offer durability and a good cut-rate.

A balanced selection between quality and cost is key. Premium products might offer better performance and longer lifespan, but there are also cost-effective options that don't compromise significantly on quality.

For further insights, this comprehensive review offers great recommendations on top flap discs and cut-off wheels for metalworking, covering a wide variety of materials and applications. In conclusion, the key to maximizing metalworking efficiency and achieving superior results lies in carefully selecting the top flap discs and cut-off wheels tailored to your specific project needs. By understanding the unique properties of each abrasive material and balancing factors such as speed, durability, and the type of finish desired, you can ensure a high-quality outcome. Remember, the right tools not only enhance performance but also contribute significantly to the safety and productivity of your metalworking tasks.

Frequently Asked Questions

What are the unique advantages of Zirconia Alumina Flap Discs for steel and stainless steel projects?

Zirconia Alumina Flap Discs offer unique advantages for steel and stainless steel projects due to their exceptional durability and ability to maintain sharpness over time. These discs are specifically engineered for heavy material removal, providing a consistent finish even with extended use. Their robust construction ensures they can withstand the demands of heavy-duty grinding and finishing tasks, making them an ideal choice for projects that require efficient and effective material removal.

How do Ceramic Flap Discs enhance precision work on heat-sensitive materials?

Ceramic flap discs are engineered to offer superior performance on stainless steel and other heat-sensitive materials due to their unique properties. These discs utilize ceramic grains that not only cut cooler but also remove material at a faster rate, significantly reducing the heat buildup that could lead to discoloration of the workpiece. The cooler cutting action coupled with the ability of ceramic grains to maintain sharpness over time makes these discs an excellent choice for precision work, ensuring both efficiency and a high-quality finish without compromising the integrity of heat-sensitive materials.

Why are Aluminum Oxide Flap Discs considered best for general-purpose metalworking?

Aluminum Oxide Flap Discs are considered best for general-purpose metalworking due to their versatility and cost-effectiveness. They are particularly suitable for tasks like rust removal and deburring on softer metals, including aluminum. While they may not offer the durability of zirconia or ceramic flap discs, they provide a balanced performance for light-duty applications, making them an economical choice for a wide range of metalworking projects. Aluminum Oxide Flap Discs strike a balance between affordability and functionality, making them an ideal solution for hobbyists and professionals working on less intensive projects.

In what applications are Silicon Carbide Flap Discs particularly effective?

Silicon Carbide Flap Discs are particularly effective in applications where a fine finish is crucial. These discs excel in working on non-metal materials such as glass, stone, and plastic, but they are also superb for metalworking tasks. Their sharp cutting ability makes them an ideal choice for precision work that requires a smooth, refined finish.

How can choosing the right cut-off wheels improve metal cutting operations?

Choosing the right cut-off wheels can significantly enhance metal cutting operations by offering cleaner cuts, improved efficiency, and longer wheel life. For instance, selecting a DeWALT Cutting Wheel can provide a fast cutting speed and extended durability, suitable for a variety of metals. On the other hand, Makita Cut-Off Wheels are praised for their balance of cutting efficiency and wheel longevity, making them popular among professionals. For tasks requiring precise work, 3M High Performance Cut-Off Wheels utilize advanced abrasive technology for smooth, fast cuts and high durability. Opting for wheels that match the material and the specific needs of your project, such as aluminum oxide wheels for ferrous metals and silicon carbide for non-ferrous materials, ensures optimized cutting performance. This personalized approach not only saves time but also enhances the safety and overall quality of the work.

What factors should be considered when selecting between flap discs and cut-off wheels for a specific metalworking task?

Selecting between flap discs and cut-off wheels involves considering their primary functions: flap discs are used for precision grinding and finishing tasks, suitable for metal fabrication and achieving a smooth finish, while cut-off wheels specialize in cutting through metal swiftly and cleanly, focusing solely on cutting without the finishing capabilities. Factors to take into account include:

Material Type and Hardness: Zirconia and ceramic flap discs are ideal for steel and stainless steel; aluminum oxide discs cater to softer metals. For cut-off wheels, choose aluminum oxide for ferrous metals and silicon carbide for non-ferrous materials.

Desired Finish: If a smooth, refined finish is required, flap discs are preferable. For straight cuts without the need for finishing, cut-off wheels are more suitable.

Durability and Performance: High-quality materials in flap discs offer longevity and consistent results. Cut-off wheels balanced for speed and durability ensure efficient cutting.

Considering these points will help you choose the right abrasive tool for your metalworking project, aligning with the material being worked on and the project's specific needs.