Reliable Coal and Coke Forges for Blacksmiths

Abana Chapter

February 10, 2024

For blacksmiths seeking to elevate the quality of their metalwork, understanding the intricacies of reliable coal and coke forges versus the modern convenience of gas forges is essential. This article dives deep into the heart of traditional blacksmithing, comparing the benefits of coal forges, known for their ability to generate high heat and imbue a sense of tradition, against the clean, user-friendly nature of gas forges. Drawing on insights from seasoned experts and communities such as ABANA.org, we aim to guide you through choosing the most efficient and reliable coal or coke forge for your blacksmithing needs, balancing the traditional art with modern practicalities.

Key Takeaways

When choosing a coal forge, consider factors such as the forge's ability to reach high temperatures, its size, and ease of ventilation to ensure it meets your blacksmithing needs.

Coke forges offer high-quality results in metalwork by providing cleaner burns and more consistent temperatures than traditional coal forges, making them suitable for those seeking efficiency and quality in their creations.

Key features of a reliable coal or coke forge include durable construction, adjustable air supply for temperature control, and ease of cleaning and maintenance.

Regular maintenance of your coal forge is essential for its longevity and performance. This includes clinker removal, airway cleaning, and firepot maintenance.

Transitioning from coal to coke can benefit blacksmiths by reducing smoke and improving the heat efficiency of the forge, though it may require adjustments in forge design and operation.

Understanding the differences and benefits of coal, coke, and gas forges can help blacksmiths select the most appropriate equipment for their craft, balancing tradition with modern convenience.

Choosing the Right Coal Forge for Your Blacksmithing Needs

When embarking on your blacksmithing journey, the choice of forge is pivotal to your success and enjoyment of this ancient craft. Coal and coke forges stand out for their high-temperature capabilities and cost-effectiveness, making them an excellent choice for traditional blacksmithing projects.

Coal Forges: Coal is praised for its economic advantage and the traditional ambiance it brings to blacksmithing. It's suitable for a variety of projects, from small-scale crafts to larger architectural pieces. However, it requires proper ventilation due to the smoke and fumes produced.

Coke Forges: A derivative of coal, coke burns cleaner and hotter, offering an efficient alternative for those seeking the high temperatures needed for forging steel. It's less smoky compared to coal, yet still mandates good workshop ventilation.

When choosing between the two, consider not just the fuel's cost and availability, but also the forge's design and how it fits within your workspace. Safety and the ability to control the fire's size and temperature are crucial factors that determine the forge's reliability and your overall satisfaction.

For more detailed insights into selecting a forge that meets your needs, exploring resources like Salt in My Coffee and Small Farmer's Journal can provide valuable guidance. These platforms offer an in-depth look at various forge options, their benefits, and practical tips for setting up a conducive blacksmithing environment.

Remember, the right forge acts as the heart of your blacksmithing endeavors. Taking the time to choose wisely will pave the way for countless hours of creating and forging ahead in your craft.

The Benefits of Using Coke Forges for High-Quality Metalwork

Coke forges play a pivotal role for blacksmiths striving for excellence in metalwork. Using coke, a refined form of coal, offers several advantages, including higher temperatures and less smoke. This fuel, integral since its historical use in ancient China and its significant contribution to the Industrial Revolution, enables the crafting of high-quality metal items with efficiency. Modern advancements continue to lean on the legacy of figures like Dud Dudley and Abraham Darby, who innovated the iron production process by introducing coke. This development not only made iron more affordable but also marked Britain's leadership in iron output, a testament to the effectiveness of coke in industrial advancements. For blacksmiths today, embracing coke forges means tapping into a heritage of technological progress that significantly reduced iron costs and boosted its utility in various industries. Opting for coke forges is not just a nod to historical efficiency but a choice for superior quality in metalwork today.

For a deep dive into the history and impact of coke in the iron industry, readers can explore this detailed historical account.

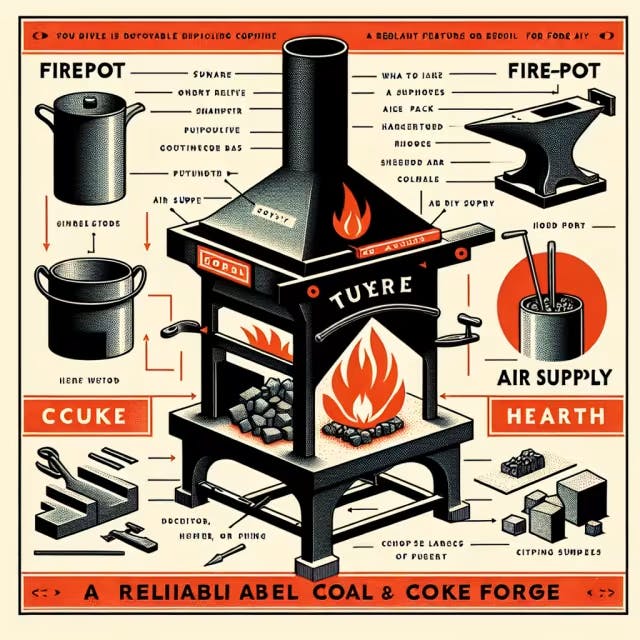

Key Features to Look for in a Reliable Coal or Coke Forge

When selecting a coal or coke forge, consider fuel efficiency. Coke's high carbon content, derived from coal through destructive distillation, emits less smoke than coal, making it a preferable choice in areas with air pollution concerns. Historical advancements, like Abraham Darby I's coke-based blast furnace in 1709, highlight coke's role in efficient metal production. Modern forges continue leveraging these benefits, focusing on designs that maximize heat generation while minimizing fuel consumption. Opt for forges that allow for easy control of airflow; this ensures optimal temperature management crucial for various blacksmithing projects. Durability is another essential factor. A well-constructed forge, designed to withstand high temperatures and continuous use, represents a wise investment. Look for materials that resist corrosion and wear, ensuring longevity and consistent performance. Lastly, consider the forge's size and portability based on your workspace and the nature of your projects. Larger forges suit extensive operations, while portable designs cater to hobbyists or those with limited space.

For more insights into coal and coke's role in historical and modern metalworking, check out this comprehensive overview.

Maintaining Your Coal Forge for Long-Term Durability

To ensure that your coal or coke forge remains reliable and durable over time, adopting a regular maintenance routine is crucial. Here are a few simple yet effective steps to keep in mind:

Clean Your Forge Regularly: After each use, removing clinker and coal residues prevents buildup which can impede airflow and heat efficiency. This step is fundamental for optimal forge operation.

Inspect for Wear and Tear: Regularly check your forge for any signs of damage, especially in areas that are exposed to the highest temperatures. Early detection of wear can prevent more significant issues later on.

Manage Airflow: Keeping the airways and tuyere (the pipe through which air is delivered to the forge) clear is crucial for controlling the forge's temperature and efficiency.

Protect from the Elements: If your forge is located outdoors, covering it when not in use will protect it from weather-related damage. Rust can be a significant problem, so addressing it early with appropriate rust inhibitors is wise.

For those seeking more in-depth advice and recommendations on forge maintenance, the community at KnifeDogs forums offers a wealth of information. Engaging with experienced blacksmiths can provide you with personalized tips based on your specific setup and needs. To dive into these discussions and gather more insights, visit KnifeDogs.

Remember, a well-maintained forge is the backbone of efficient and successful blacksmithing. Taking the time to care for your equipment pays off in both the short and long term, ensuring that your forge remains a reliable tool in your blacksmithing endeavors.

Transitioning from Coal to Coke: What Blacksmiths Should Know

When shifting from coal to coke in blacksmithing, understanding the differences in performance, cost, and environmental impact is essential. Coke, a derivative of coal, offers a cleaner burn with fewer impurities, which can enhance the quality of metalwork. The transition, however, requires adjustments in forge design and operation due to coke’s different burning characteristics.

Feature | Coal | Coke |

Burn Quality | Produces more smoke and soot | Burns cleaner with less smoke |

Heat | Uneven heating | Consistent and high heat |

Cost | Generally cheaper | More expensive initially |

Availability | Widely available | Less accessible in some areas |

For more insights on this transition, check out discussions among the blacksmith community here.

Remember, adapting your techniques to coke’s characteristics will ensure a smoother transition and yield better forging results. In conclusion, the choice between reliable coal and coke forges is pivotal for blacksmiths, blending tradition with modern efficiency. By considering factors such as fuel type, forge design, and maintenance requirements, blacksmiths can ensure their forge not only meets their metalworking needs but also stands the test of time. Transitioning from coal to coke offers an opportunity to enhance metalwork quality while adhering to environmental standards, making an informed choice essential for any aspiring or professional blacksmith.

Frequently Asked Questions

What are the advantages of using coal forges for traditional blacksmithing projects?

Coal and coke forges offer significant advantages in traditional blacksmithing projects due to their high-temperature capabilities and cost-effectiveness. Coal forges are valued for their economic advantage and the traditional ambiance they contribute to the craft, making them versatile for various project sizes. However, they necessitate proper ventilation due to smoke and fumes. On the other hand, coke forges, derived from coal, burn cleaner and hotter, presenting an efficient alternative for achieving the high temperatures required for forging steel with less smoke, yet still requiring good workshop ventilation. When choosing between coal and coke forges, it's essential to consider not only the fuels' cost and availability but also the forge design and its compatibility with your workspace, alongside the necessity for safety and the ability to control the fire's size and temperature.

How do coke forges enhance the quality and efficiency of metalwork in blacksmithing?

Coke forges enhance the quality and efficiency of metalwork in blacksmithing due to their ability to reach higher temperatures and produce less smoke compared to coal forges. This results in a cleaner and more efficient forging process, essential for working with steel. In addition, coke's high carbon content ensures a more consistent heat, crucial for the uniform treatment of metals. Opting for a coke forge means tapping into a legacy of industrial efficiency, where historical advancements made metal more affordable and versatile for various applications. Hence, using coke forges not only continues a tradition of technological progress but also aligns with modern needs for quality and environmental consideration in metalwork.

What are the key considerations when choosing between a coal and a coke forge for your workspace?

When deciding between a coal and a coke forge, key considerations include the following:

Fuel Efficiency and Environmental Impact: Coke burns cleaner and hotter than coal, making it ideal for forging steel while producing less smoke and suiting areas with strict air quality regulations.

Maintenance and Forge Design: Opt for a forge that allows easy control of airflow for temperature management, is constructed with durable materials to withstand high temperatures and continuous use, and fits the size and portability needs of your workspace.

Historical and Modern Usage: Understanding coke's role in the advancement of metalworking can provide insights into its efficiency and cost-effectiveness for your projects.

Choosing the right forge depends on balancing these factors to meet your specific blacksmithing requirements and environmental considerations.

How can regular maintenance ensure the longevity and reliability of coal and coke forges?

Regular maintenance is key to ensuring the longevity and reliability of coal and coke forges. Key steps include regularly cleaning out clinker and coal residues to maintain airflow and heat efficiency, inspecting the forge for wear and tear to catch and address issues early, keeping the airways and tuyere clear for optimal temperature control, and protecting the forge from the elements to prevent rust and weather-related damage. Implementing a routine that encompasses these practices will greatly enhance the performance and lifespan of your forge, making it a dependable tool in your blacksmithing craft.

What are the environmental impacts of choosing coke over coal for blacksmithing?

Choosing coke over coal for blacksmithing has notable environmental impacts due to coke's cleaner burning properties. While both materials are derived from coal, coke undergoes a process that removes much of the volatile substances, resulting in a fuel that burns at higher temperatures with less smoke and fewer impurities. This reduction in particulate emissions is beneficial for air quality, especially in settings where ventilation may be limited. Additionally, the higher efficiency of coke means that less fuel is required to achieve the same forging temperatures as coal, potentially reducing the overall carbon footprint of blacksmithing activities. However, it's important to note that the production process of coke itself is energy-intensive and has its own environmental considerations.