Professional Knife Making Tools and Techniques

Abana Chapter

February 09, 2024

Diving into the intricate world of professional knife making tools and techniques offers both novices and seasoned craftsmen a path to enhancing their skills and end products. Sharpening, a cornerstone of knife making, not only shapes the blade but also refines its precision, efficiency, and safety, ensuring minimal material waste and reduced risk of hand injuries. This article pulls from expert insights, like those from Peachey Conservation, to guide readers through the essential tools for knife making beginners, advanced sharpening techniques, and the pivotal processes of forging and heat treatment, equipping them with the knowledge to choose the right materials for high-quality knives while adhering to paramount safety practices.

Key Takeaways

Sharpening is fundamental in knife making, affecting a blade's precision, efficiency, and safety, while also minimizing material waste.

Beginners in knife making should prioritize acquiring essential tools that facilitate both crafting and sharpening processes.

Advanced sharpening techniques can elevate the quality of knives by enhancing edge durability and cutting performance.

Understanding the art of forging and heat treatment is crucial for creating knives with excellent edge retention and toughness.

Choosing the right materials is key to manufacturing high-quality knives, considering factors like blade strength, corrosion resistance, and aesthetic appeal.

Adhering to safety practices is paramount in knife making to prevent injuries and ensure a safe working environment.

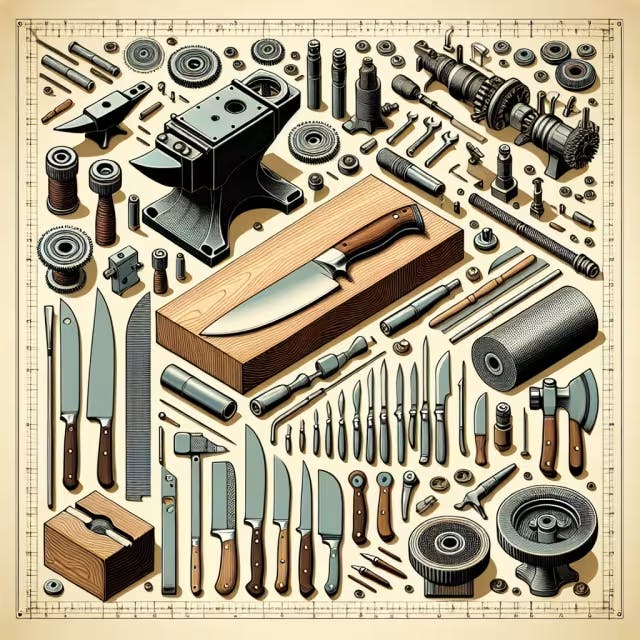

Essential Tools for Knife Making Beginners

Venturing into the craft of knife making requires familiarity with a range of specialized tools. Beyond the basics of forging and heat treatment, detailed work on a blade's surface and handle demands precision instruments. A few foundational tools can set beginners on the right path:

Belt Grinder: A versatile piece of equipment, essential for shaping and sharpening the blade. Selecting a model with adjustable speed can offer more control over the material removal process.

Drill Press: Ideal for making precise holes in the knife handle. Opt for a press with variable speed settings to accommodate different materials.

Files and Rasps: These manual tools allow for fine adjustments and shaping, especially in areas where the grinder cannot reach.

Workbench Vise: Secures the knife safely, providing stability during intensive tasks such as filing or drilling.

Each tool serves a specific purpose in the intricate process of crafting a knife. A belt grinder shapes the blade, while the drill press and files fine-tune the handle and intricate details of the design. The workbench vise keeps everything secure, ensuring safety and accuracy.

Beginners should gradually acquire these tools, focusing first on those that match their initial projects. Mastery in using these tools opens up endless possibilities in crafting high-quality knives. For more detailed information on starting your knife-making journey, consider exploring resources and tutorials that offer step-by-step guidance such as this comprehensive article on knife making.

Advanced Techniques for Professional Knife Sharpening

Professional knife sharpening stands as a critical aspect of craftsmanship, underscored by insights from Peachey Conservation. This technique bolsters precision, efficiency, and safety, reducing both material waste and the risk of hand injuries. A pivotal part of sharpening involves mastering stropping techniques. Correct bevel angle maintenance during this process is essential to avoid an overly obtuse edge, which could diminish cutting efficiency. Horsebutt leather is highlighted for strops due to its durability and the appropriate firmness it offers.

Testing sharpness and addressing blade chips effectively are also integral. For those delving deeper into the art of knife maintenance, a selection of resources and reviews on Peachey’s workshops offers invaluable guidance. Understand more about the nuances of professional knife sharpening from Jeff Peachey's insights.

The Art of Knife Making: Forging and Heat Treatment

Knife making combines skill, precision, and the right tools and techniques. Two critical stages in this craft are forging and heat treatment, each playing a vital role in the creation of a durable and sharp blade.

Forging: Shaping the Blade

Forging involves heating the metal to a high temperature, making it malleable enough to shape. Knife makers use a variety of hammers and anvils to forge blades into desired shapes. The type of hammer and anvil used can significantly affect the outcome, allowing for various blade shapes and sizes.

Hammer: Transforms the heated metal into the preliminary shape of the blade.

Anvil: Provides a solid surface against which the metal is forged.

Heat Treatment: Ensuring Durability

Heat treatment is crucial for hardening the blade and enhancing its durability. This process involves heating the forged blade to a high temperature and then cooling it rapidly (quenching) followed by tempering.

Quenching: Rapid cooling, usually in oil or water, to harden the steel.

Tempering: Heating the blade at a lower temperature to remove some of the brittleness.

Stage | Process | Purpose |

Forging | Heating and hammering the metal | Shape the blade |

Heat Treatment | Quenching and tempering | Harden the blade and enhance durability |

Each stage requires precision and careful control to achieve the perfect balance of hardness and toughness in the blade. Mastery over these techniques can significantly elevate the quality and efficiency of knife making. To delve deeper into these processes, consider exploring this informative guide on knife forging.

Choosing the Right Materials for High-Quality Knives

Selecting the right materials is a pivotal aspect of professional knife making. The choice of steel for the blade, along with the handle materials, significantly affects the knife's functionality, durability, and aesthetic appeal. Here's a quick glance at widely recommended materials:

Material Type | Characteristics | Recommended Use |

Carbon Steel | High sharpness, easier to sharpen | Chef knives, hunting knives |

Stainless Steel | Rust-resistant, less maintenance required | Everyday carry knives, dive knives |

Titanium | Lightweight, highly corrosion-resistant | Tactical knives |

Wood | Warmth, classic look, customizability | Custom knife handles |

Micarta | Durable, water-resistant, good grip | Outdoor and tactical knife handles |

G10 | Very tough, water-resistant, various colors | High-end custom knife handles |

For any knife maker aiming at crafting knives that combine high performance with exquisite craftsmanship, understanding and selecting the right materials is key. Whether it's choosing between high carbon steel for its renowned edge retention or opting for stainless steel for its rust resistance, each material brings its unique properties to the finished product.Learn more about the properties of different steel types used in knife making. Similarly, the handle material can significantly influence the knife's balance, grip, and overall aesthetics. The choice should align with the knife's intended use and the user's preferences, ensuring it's not only beautiful but also functional and durable.

Safety Practices Every Knife Maker Should Follow

When crafting knives, prioritizing safety ensures not only the well-being of the maker but also the integrity of the final product. Here are some core practices that should never be overlooked:

Wear Protective Gear: Essential items include safety glasses to protect eyes from flying debris, gloves to guard hands during handling and grinding, and a dust mask or respirator to prevent inhalation of harmful particles.

Utilize Proper Ventilation: Metal grinding and polishing can release hazardous particulates. A well-ventilated workspace reduces risk.

Follow Equipment Guidelines: Always adhere to manufacturer instructions for tool use and maintenance. Misuse can lead to accidents or tool damage.

Store Tools Wisely: Secure storage prevents unintended injuries and preserves tool condition. Knives should be sheathed or stored in racks, and other sharp objects should be kept in clearly labeled, safe locations.

Regular Maintenance: Keep all equipment in top-notch condition. Dull tools require more force to use, increasing the risk of slipping and injury.

Emergency Preparedness: Have a first-aid kit readily available and be familiar with basic first aid procedures. Know the location of the nearest fire extinguisher and how to use it.

Integrating these practices into the everyday routine solidifies a foundation of safety that complements the professional knife making tools and techniques. Adopting such measures not only enhances productivity and quality but also demonstrates a commitment to craftsmanship's highest standards. For an in-depth guide on implementing a robust safety protocol in professional environments, visiting Walmart and Sam’s Club's policies can offer additional insights into maintaining high safety and ethic standards across various production processes. In conclusion, mastering professional knife making tools and techniques involves a blend of acquiring the right equipment, such as a belt grinder and drill press, and honing skills in sharpening, forging, heat treatment, and material selection. Safety remains paramount, ensuring both the knife maker's well-being and the integrity of the knives produced. With dedication to these principles, one can craft high-quality, functional, and aesthetically pleasing knives.

Frequently Asked Questions

What are the essential tools for beginning knife makers?

For beginners in knife making, there are several essential tools that are fundamental to the craft. These include:

Belt Grinder: Crucial for shaping and sharpening the blade efficiently, with adjustable speed for better control.

Drill Press: Used for drilling precise holes in knife handles, with variable speed settings to accommodate different materials.

Files and Rasps: Allow for detailed adjustments and fine shaping in areas not accessible by the grinder.

Workbench Vise: Provides stability and safety, securing the knife during tasks such as filing or drilling.

These tools form the backbone of knife making, enabling the creator to shape, detail, and finish a knife effectively. Mastery of these tools opens up expansive possibilities in the craft, allowing for the production of high-quality knives.

How does the choice of material influence the functionality and durability of a knife?

The choice of material for both the blade and handle of a knife profoundly influences its functionality, durability, and aesthetic appeal. Materials like carbon steel, renowned for their sharpness and ease of sharpening, are ideal for chef and hunting knives, while stainless steel, with its rust resistance and lower maintenance requirement, suits everyday carry and dive knives well. For handles, options range from wood, which offers warmth and a classic look, to synthetics like Micarta and G10, known for their durability, water resistance, and good grip. Moreover, the material selection directly impacts the knife's balance, grip, and overall performance, making it crucial to align with the intended use and user preferences to ensure the knife is not only visually appealing but also highly functional and long-lasting.

What are the critical stages in the knife making process for creating a durable and sharp blade?

The critical stages in the knife making process that ensure the creation of a durable and sharp blade include forging, heat treatment, and selecting the right materials. During the forging process, the metal is heated to high temperatures and shaped using hammers and anvils, allowing for the desired blade shape. Heat treatment, involving quenching and tempering, is crucial for hardening the blade and enhancing its durability. The choice of materials, from the type of steel for the blade to the handle composition, significantly affects the knife's functionality, durability, and aesthetic appeal. Mastery over these processes and careful selection of materials are essential for crafting high-quality knives.

What are the best practices for ensuring safety during the knife making process?

Ensuring safety during knife making involves wearing protective gear such as safety glasses, gloves, and a dust mask or respirator to shield against flying debris and harmful particles. It's vital to maintain a well-ventilated workspace to minimize exposure to hazardous substances emitted during grinding and polishing. Proper usage and maintenance of equipment following manufacturer guidelines are crucial to avoid accidents or damage to tools. Tools should be stored securely to prevent unintended injuries, with knives sheathed or kept in racks. Regular maintenance of equipment, ensuring tools are sharp and in good condition, reduces the force needed and mitigates the risk of slipping and injury. Lastly, having a first-aid kit ready and knowledge of basic first aid procedures, along with easy access to a fire extinguisher, prepares you for emergency situations. These measures not only safeguard the maker but also uphold the integrity of the crafting process, ensuring high-quality outcomes.

How can mastering professional knife sharpening techniques enhance the quality of your craftsmanship?

Mastering professional knife sharpening techniques significantly enhances the quality of craftsmanship by ensuring that each blade is honed to its optimal sharpness, which is critical for performance and durability. Proper sharpening reduces material waste and lowers the risk of accidents by maintaining a precise edge, minimizing the effort required during use. Mastery of stropping and maintaining the correct bevel angle, for instance, directly impacts a knife's cutting efficiency, thus elevating the overall quality of the product. Furthermore, understanding how to address blade chips and test sharpness are pivotal skills that ensure each knife meets high standards of functionality and aesthetics.