High-Quality Tom Tongs Guide for Blacksmiths

Abana Chapter

February 23, 2024

Embarking on a blacksmithing project requires precision, skill, and the right tools. One of the most essential implements in a smith's arsenal is a set of high-quality tom tongs, designed to grip and manipulate hot metals with ease and safety. This guide offers a comprehensive look at understanding tom tongs for blacksmithing projects, helping you select the right pair for your forge work while emphasizing durability, material considerations, and essential features, along with maintenance tips to ensure your tools endure the demanding conditions of the forge.

Key Takeaways

Tom tongs are crucial for safely gripping and manipulating hot metals during blacksmithing projects.

It's important to select the right pair of tom tongs to match the specific needs of your forge work.

The durability and material quality of tom tongs are vital to withstand the high temperatures and rough conditions of blacksmithing.

High-quality tom tongs should exhibit essential features like proper grip, balance, and ergonomic design for efficient functionality.

Regular maintenance of tom tongs is necessary to keep them in good working condition and ensure their longevity.

Recognizing the investment in the right tom tongs can enhance both the safety and the quality of blacksmithing work.

Understanding Tom Tongs for Blacksmithing Projects

Blacksmiths know that the right tools make all the difference in crafting quality metalworks, and this is certainly the case with tongs. Specifically, tom tongs are designed to grip and maneuver hot metal with precision and safety. But selecting the right pair from a range of options can be daunting.

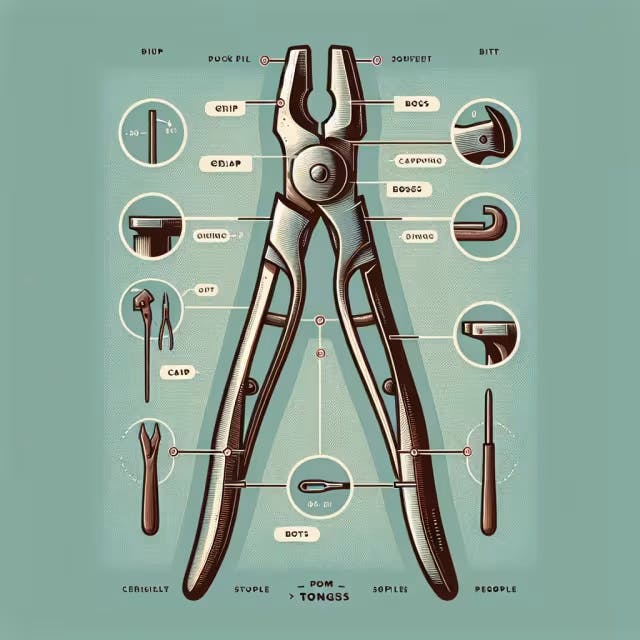

Key to choosing high-quality tom tongs is understanding jaw design and construction material. Jaws should match the shape of the workpiece to minimize slippage, and they can vary from flat and box to V-bit and bolt designs. Reliable tom tongs are typically forged from high-carbon steel for optimal heat resistance and durability.

Here's a quick guide to help you discern which tom tongs will best serve your blacksmithing needs:

Type of Tong | Best for Gripping | Material |

Flat Jaw | Sheets and flat stock | High-Carbon Steel |

Box Jaw | Square and rectangular bars | High-Carbon Steel |

V-Bit Jaw | Round and square rods | High-Carbon Steel |

Bolt Jaw | Bolts and round stocks | High-Carbon Steel |

Remember, proper maintenance, such as regular cleaning and avoiding quenching in water, extends the lifespan of your tom tongs. With the aid of this guide and their existing craftsmanship skills, blacksmiths can confidently select the right tools to enhance their project outcomes. To explore more about forging tools and blacksmithing techniques, Crafting Excellence offers valuable insights.

Selecting the Right Tom Tongs for Your Forge Work

When it comes to blacksmithing, having the right tools can significantly impact the quality and efficiency of your work. Among these tools, the correct pair of tongs is paramount; Tom Tongs, known for their durability and versatility, are a popular choice for many blacksmiths.

Criteria | Description |

Material | Tom Tongs are typically made from high-carbon steel, providing strength and resilience against high temperatures. |

Size & Shape | The size and shape of the tongs should match the size of the stock you're working with, ensuring a secure grip. |

Handle Length | Longer handles provide more leverage but can be cumbersome, whereas shorter handles offer more control. Finding a balance is key. |

Type | There are various types of Tom Tongs, such as flat-nose, bolt, V-bit, and scrolling tongs, each suited for different tasks. |

When selecting high-quality Tom Tongs, consider the specific tasks you'll be performing. Are you frequently turning heavy billets? Maybe V-bit tongs would serve you best. For more delicate work, such as making scrollwork, scrolling tongs with a lighter grip might be more appropriate.

Select tongs that allow you to maintain a comfortable grip and control over your work. Your tongs should feel like an extension of your hand—too heavy, and you’ll tire quickly; too light, and you may not be able to manage the materials effectively.

Finally, it's crucial to purchase from credible suppliers to ensure the tongs are well-crafted and meet industry standards. Forging suppliers such as Centaur Forge and Blacksmiths Depot have a reputation for providing high-quality tools, making them fitting choices for sourcing Tom Tongs. Consider reading current reviews and product feedback from fellow blacksmiths to gain insights into the longevity and performance of the tongs you're considering.

By carefully choosing a high-quality pair of Tom Tongs, you'll not only improve your blacksmithing technique but also invest in a tool that will serve you well for years to come. Always prioritize functionality and comfort in your selection for the best results in your forge work.

Tom Tongs Durability and Material Considerations

Selecting the right pair of tongs is crucial as they are the blacksmith's primary tool for holding hot metal. Tongs that aren't up to the task can lead to workpiece slippage, inefficiency, and potential injury. To ensure the highest safety and performance, pay close attention to the materials used in their construction.

Tongs are typically forged from high-carbon steel, which provides both strength and durability under high temperatures. A good pair of tongs will have been properly heat-treated to withstand the rigors of blacksmithing without becoming brittle or losing their grip. The key to this durability lies in the balance of carbon within the steel; too much and the tongs become brittle, too little and they lack the necessary strength.

For an idea of the durability you should expect from a quality pair of tongs, consider the benchmark set by renowned tool suppliers:

Material | Durability Standard |

High-Carbon Steel | Excellent |

Mild Steel with Reinforcement | Good with Proper Maintenance |

Tool Steel | Superior |

Proper care and maintenance also play a role in longevity. Regular cleaning and occasional re-coating with a protective layer, such as oil or wax, can prevent rust and extend the life of the tongs. Keep in mind that over time, even the best materials can succumb to the stresses of use, which makes routine inspections important to catch any early signs of wear or damage.

For more insights into selecting the appropriate materials for your blacksmithing needs, a comprehensive guide to high-quality tom tongs provides the necessary depth to make an informed decision. Remember, a blacksmith's efficiency is greatly affected by the quality of the tools they use, so investing in the right pair of tongs can pay off in the long term with increased productivity and safety.

Essential Features of High-Quality Tom Tongs

When selecting tom tongs for blacksmithing, durability is a key factor. Look for ones made from high-grade steel that can withstand the intense conditions found in metalworking. Grip is another crucial aspect; tongs with a comfortable handle will reduce hand fatigue, allowing for longer work sessions.

Precision is vital when working with various sizes and shapes of metal—well-designed tom tongs with a firm grip can handle both small and large pieces with ease. Moreover, proper heat treatment in manufacturing ensures longevity and resistance to wear.

Aligning with the best practices, top-tier tom tongs feature a design that caters to specific forging needs. For instance, tongs meant for holding flat stock will differ significantly from those used to manage round stock.

Feature | Benefit |

High-Grade Steel | Ensures durability and longevity under high heat |

Comfortable Handle | Reduces hand fatigue for extended use |

Versatile Grip Design | Essential for precision and handling different shapes |

Proper Heat Treatment | Key for durability and wear resistance |

Task-Specific Models | Provides precision for various blacksmithing tasks |

Tips for Maintaining Your Tom Tongs for Longevity

Proper care extends the life of blacksmithing tools, particularly high-quality tom tongs. Regular maintenance is a key factor in ensuring that these tools remain functional and operational for years to come. Below are straightforward strategies for preserving your tom tongs:

Clean After Use: Always remove debris and scale after each session. A wire brush works well for this task.

Apply Protective Coating: Coat the tongs with a light layer of oil to prevent rust—common choices include linseed oil or a simple WD-40 application.

Inspect for Damage: Before and after use, check for any signs of cracks or wear that could lead to failure during operation.

Store Properly: Tongs should be kept in a dry, organized environment. Moisture can lead to rust, which is a primary enemy of metal tools.

Avoid Overheating: Don't expose the tongs to excessive heat for long periods as this can lead to a loss of temper and strength in the metal.

Adhering to these practices ensures that your tom tongs will be a reliable blacksmithing partner, capable of withstanding the rigors of metalworking. Integrating the knowledge of selecting the most suitable Tom Tongs that align with your blacksmithing needs, paying attention to the balance and comfort they provide, and committing to diligent maintenance, are the keystones for any blacksmith seeking long-term success in the forge. The hallmark of a high-quality Tom Tong lies in its construction and compatibility with your craft, so investing in tools that offer the right fit and durability from reputable suppliers is an essential step. Remember, the care you put into your Tom Tongs is directly reflected in the quality and efficiency of your workmanship.

Frequently Asked Questions

What are the key factors to consider when choosing high-quality tom tongs for blacksmithing?

High-quality tom tongs are essential for blacksmiths to handle hot metal with precision and safety. When choosing tom tongs, consider the following key factors:

Material: Opt for tongs made of high-carbon steel, as they offer the strength, durability, and heat resistance needed for intense blacksmithing tasks.

Jaw Design: Select a jaw design that matches the shape of your workpiece, whether that be flat, box, V-bit, or bolt jaw, to ensure a secure grip and minimize slippage.

Maintenance: Regularly clean your tongs and avoid quenching them in water to prevent rust and extend their lifespan.

By keeping these factors in mind and purchasing from reputable suppliers, blacksmiths can secure tongs that enhance their craftsmanship and last through years of forging work.

How do the materials of tom tongs affect their durability and heat resistance?

The durability and heat resistance of tom tongs are significantly influenced by the materials from which they are made. High-carbon steel is commonly used due to its resilience under high temperatures, essential for enduring the rigorous blacksmithing environment. Proper maintenance, like regular cleaning and avoiding extreme heat exposure, is crucial to prolong their lifespan and maintain a good grip, indicative of quality tongs.

What are the benefits of selecting tom tongs based on the specific tasks in blacksmithing?

When selecting tom tongs for your blacksmithing tasks, consider the following benefits of choosing the right pair:

Material Compatibility: Using tongs made from high-carbon steel ensures resilience under the intense heat of forging and contributes to the longevity of the tool.

Efficiency: The proper jaw design, such as flat, box, V-bit, or bolt, allows you to securely grip the specific shape of the material you're working with, reducing slippage and increasing control.

Safety: A well-fitted tong reduces the likelihood of accidents caused by the workpiece slipping or being dropped.

Selecting tongs that match the specific tasks at hand can greatly improve the results of your blacksmithing, making the process safer, and more efficient, and helping to produce quality metalwork.

How can proper maintenance extend the lifespan of your blacksmithing tom tongs?

Proper maintenance is crucial in extending the lifespan of your blacksmithing tom tongs. Here are some guidelines to keep them in top condition:

Clean After Use: Remove debris, scale, and residue with a wire brush after each forging session to prevent build-up.

Avoid Quenching: Never cool your tongs in water, as the rapid temperature change can cause the high-carbon steel to become brittle.

Apply Protective Coating: Protect the tongs from rust with a light coat of oil or wax, especially if you're storing them for an extended period.

Following these simple steps will help maintain the integrity and functionality of your tom tongs, ensuring they remain a valuable tool in your blacksmithing endeavors.

Where can you find reliable suppliers for high-quality tom tongs in the US?

You can find reliable suppliers for high-quality tom tongs in the US at reputable blacksmithing and forging equipment stores such as Centaur Forge and Blacksmiths Depot. These suppliers are known for their quality tools and have a range of tom tongs designed to handle different shapes and sizes of metal with durability and precision. Always look for tongs made from high-carbon steel with proper heat treatment for extended longevity and choose a design that matches your specific forging needs. Reading reviews and feedback from other blacksmiths can also provide valuable insights into the performance and durability of the tongs.