Finishing Supplies for Metalworking and Smithing

Abana Chapter

February 05, 2024

Crafting the perfect piece in metalworking and smithing goes beyond the heat of the forge and the strike of the hammer; it's about understanding the nuances of the finishing process. For artisans skilled in transforming iron and steel into intricate gates, tools, and weapons, the journey from a heated piece of metal to a finished product is steeped in tradition and technique. In today's market, selecting the right finishing supplies for metalworking and smithing can make all the difference in showcasing the artisan's expertise and delivering a piece that stands out not only for its form but also for its impeccable finish.

Key Takeaways

Metal finishing is a crucial step in metalworking and smithing that requires a deep understanding of materials and techniques to achieve a distinctive and professional finish.

Selecting the appropriate abrasives is essential to prepare the metal surface effectively for subsequent finishing processes.

The choice of coatings and sealants is critical for protecting the crafted items from environmental factors and for enhancing their appearance and longevity.

Having the right polishing tools is integral for obtaining a professional look, as they help in refining and highlighting the intricate details of metalwork.

Safety cannot be overstated when working with metal finishing chemicals; proper handling, storage, and use of protective gear are necessary to prevent accidents and health hazards.

The artisan's expertise in choosing and using the right finishing supplies can significantly influence the final aesthetic and quality of the metal piece.

Understanding the Essentials of Metal Finishing Supplies

For those involved in metalworking and smithing, adhering to safety regulations is as crucial as having the right finishing supplies. Notably, the REACH regulation by the EU plays a pivotal role in ensuring the safe management of chemicals used in this industry. Comprehending REACH regulations is essential for metalworking professionals as it can influence the selection and use of finishing supplies.

Key Considerations for Finishing Supplies:

Chemical Compliance: Supplies must comply with REACH, obliging manufacturers to demonstrate safe handling and management of chemicals.

Substance Authorization: Authorization under REACH ensures that only approved chemicals are utilized in the finishing process.

Hazard Classification: Proper labeling and classification prevent misuse and promote safety in the workspace.

Failure to comply with these standards can lead to penalties and compromised safety. While REACH is an EU regulation, businesses outside the EU must also comply via EU representatives when they export to the EU market. It is important to select finishing supplies that are not only effective but also align with current health and environmental standards. For more on REACH compliance and guidelines, you can visit the European Chemicals Agency, which provides extensive resources and assistance.

Consideration | Detail |

Chemical Use | Supplies must adhere to REACH registration, evaluation, and authorization to ensure safe usage. |

Compliance Responsibility | Suppliers are responsible for ensuring that their products meet current safety regulations. |

Labelling | Correct classification and labelling in line with CLP regulations are mandatory. |

Environmental Health | Products should minimize impact on the environment and human health. |

Thus, while choosing finishing supplies for metalworking and smithing, professionals must prioritize safety by selecting products that conform to legal and environmental standards. This diligent approach helps safeguard the well-being of artisans and the environment, while also aligning with global regulatory expectations. Remember to consult the latest guidelines to ensure products used in your metal finishing operations comply with the aforementioned criteria.

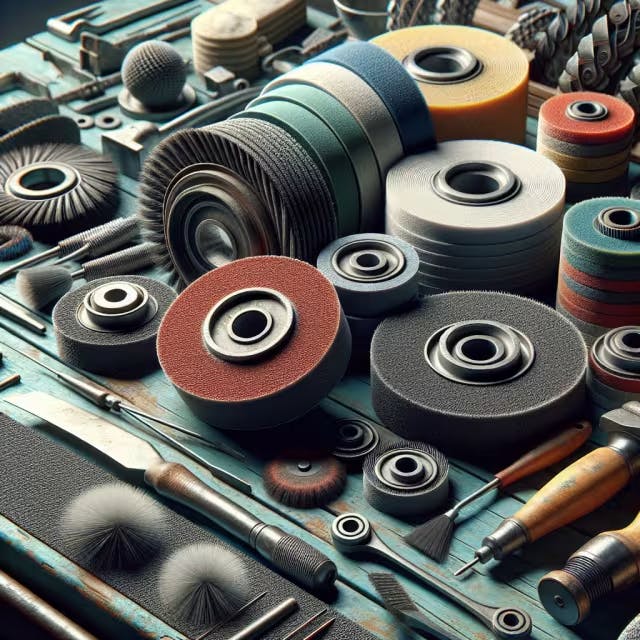

The Best Abrasives for Metalworking

When selecting abrasives for metalworking, the right choice can significantly impact project outcomes. A variety of materials and tools are available, and understanding their uses ensures a quality finish. Aluminum oxide is a common abrasive for general-purpose metal grinding. It's cost-effective and works well on iron, steel, and other metals. Silicon carbide, on the other hand, is harder and sharper, making it an excellent option for materials like brass, aluminum, and titanium.

Consider the grit size as well. Grit refers to the size of the abrasive particles and is crucial for achieving a desired surface finish. Coarse grits remove material quickly but leave rough surfaces, while finer grits provide a smoother finish but take more time. Here's a quick reference for common grit sizes and their general applications:

Grit Size Range | Application |

24-60 | Rough grinding |

80-180 | Intermediate machining |

220 and higher | Fine finishing/polishing |

Ceramic abrasives are suitable for high-stress applications due to their durability and ability to stay sharp longer. Zirconia alumina is ideal for heavy-duty material removal on steel and stainless steel.

Remember, choosing the right type of abrasive directly affects the efficiency and results of your metalworking projects. By understanding the specific properties of each abrasive type, you can achieve optimal results and prolong the lifespan of your tools. Seek out reputable suppliers for top-quality finishing supplies for metalworking and smithing.

Choosing the Right Coating and Sealants for Smithing

Selecting the appropriate coatings and sealants is a crucial step in ensuring durability and aesthetics in metalworking and smithing projects. The market offers a range of products designed to protect metals from corrosion, wear, and environmental factors. Below is a guide to some of the most commonly utilized materials:

Type | Properties | Usage |

Clear Lacquer | Quick-drying, transparent finish | Small decorative items |

Epoxy Coatings | Durable, resistant to chemicals | Industrial equipment, vehicles |

Oil & Wax | Natural look, easy to apply | Hand tools, culinary items |

Powder Coating | Thick, even finish, minimal environmental impact | Outdoor metal furniture, machinery |

Epoxy coatings, for example, are ideal for objects that encounter heavy usage and exposure to harsh chemicals, offering an extremely robust and long-lasting finish. On the other hand, oil and wax finishes can provide a more natural sheen, suitable for items like handmade knives or decorative wrought ironwork which requires a softer touch that complements the craftsmanship. For pieces that are exposed to significant weather elements, consider using powder coating — highly efficient in providing an attractive yet protective finish that combats rust and degradation.

For hobbyists and professionals alike, it's essential to match the finishing method to the intended use of the metal object. Ensure to review product specifications and safety data sheets for optimal results and safe application. Always handle finishing supplies with care and follow the recommended guidelines for use and disposal.

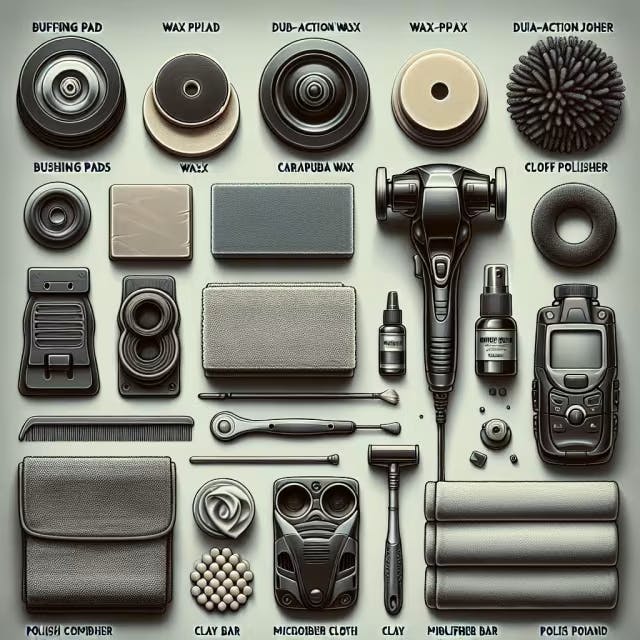

Essential Polishing Tools for a Professional Finish

To achieve a professional finish in metalworking and smithing, a variety of tools comes into play, highlighting the importance of precision and meticulous post-processing. Some must-have items include:

Spatulas and X-Acto Knives: These tools are critical for fine-tuning and removing any excess material without damaging the underlying surfaces. Their sharp blades work well for trimming and shaping to create seamless joints and edges.

Deburring Tools: No metalwork is complete without deburring to remove rough ridges and edges. This process enhances the safety and aesthetic of the final product.

Pliers: They provide the grip and leverage necessary to bend, twist, and manipulate metal components into place.

Sanding Supplies: Sandpapers with varying grits are essential to smooth out surface imperfections and prep the metal for finishing coats.

Digital Calipers: Accuracy is crucial, and digital calipers measure dimensions to fractions of a millimeter, ensuring pieces fit together perfectly.

Tweezers: Maneuvering and placing small parts becomes effortless with tweezers, which are especially useful in intricate designs.

Hex Keys and Screwdrivers: These tools are indispensable for tightening and adjusting components, ensuring everything is secure.

To maintain the quality of work and equipment, items like glue sticks and masking tape should be readily available. Glue sticks can help in affixing parts temporarily during assembly, while masking tape can protect areas from scratches or unwanted paint. Adhesion sheets also play a role in ensuring your pieces remain in place during the finishing process.

To go along with this, take insights from experts by considering this comprehensive toolkit tailored for enhancing 3D print quality, which shares common ground with metalworking tools and techniques in achieving professional results.

Safety Tips for Handling Metal Finishing Chemicals

When handling chemicals related to metal finishing and smithing, adhering to proper safety protocols is crucial to protect your health and prevent potential accidents. Personal protective equipment (PPE) is your first line of defense, ensuring you shield yourself from harmful exposure. This includes using gloves, goggles, face shields, and aprons suited for chemical resistance. Ensure the workspace is well-ventilated to diffuse fumes and consider installing exhaust systems if working with particularly volatile substances.

A key practice is keeping chemical containers tightly sealed when not in use, and storing them in a designated, secure area to avoid any accidental spills or contamination. Additionally, you should clearly label all chemicals, possibly using a color-coding system, to prevent mix-ups which can lead to dangerous reactions.

Be mindful that emergency procedures are in place, such as having an eyewash station and a shower nearby, to quickly address any exposure. Lastly, always dispose of chemicals according to local environmental regulations to minimize ecological impact.

For more detailed guidance on handling these substances safely, refer to the comprehensive manual provided by The Department of Toxic Substances Control.

Safety Equipment | Description |

Gloves | Chemical-resistant gloves to prevent skin contact. |

Goggles | To protect eyes from splashes. |

Face Shield | To guard the face against chemical splashes. |

Apron | Chemical-resistant to prevent chemical contact with clothing. |

Remember, being proactive and cautious when working with metal finishing chemicals can significantly reduce the risk of hazardous incidents. In summary, selecting the appropriate finishing supplies for metalworking and smithing is essential for achieving professional results that comply with safety and environmental regulations. From the choice of abrasives to the application of durable coatings, and the utilization of specialized tools, each aspect plays a significant role in the quality of the final product. By adhering to safety protocols and choosing the right materials for the job, professionals can ensure that their work not only looks outstanding but is also produced in a responsible and compliant manner.

Frequently Asked Questions

What are the key considerations when choosing finishing supplies for metalworking and smithing?

When choosing finishing supplies for metalworking and smithing, key considerations include:

Chemical Compliance: Ensure that supplies comply with safety regulations, particularly the REACH regulation if operating within or exporting to the EU, which mandates the safe management of chemicals.

Material and Tool Selection: Select abrasives like aluminum oxide or silicon carbide based on the type of metal and desired finish, considering factors such as grit size for surface finishing.

Coatings and Sealants: Choose appropriate coatings like epoxy for durability or oil and wax for a natural look, based on the item's intended use and exposure to elements.

Ensure the selection aligns with health and environmental standards, handling safety protocols with due care, and employing personal protective equipment for a safer workspace.

How do REACH regulations affect the use of chemicals in metal finishing?

REACH regulations affect the use of chemicals in metal finishing in several ways:

Chemical Compliance: Metal finishing supplies must comply with REACH directives, which requires manufacturers to prove that chemicals are managed and handled safely.

Substance Authorization: Under REACH, metal finishing processes are allowed only to use authorized substances, ensuring that harmful chemicals are not employed in operations.

Hazard Classification: All chemicals used in the finishing processes must be properly labeled and classified to prevent misuse and to enhance safety measures in the workplace.

Non-compliance with REACH regulations can result in penalties and jeopardized safety. Although REACH is an EU regulation, it also impacts businesses outside the EU that export to the EU market, as these businesses are required to ensure compliance through EU representatives. Therefore, when choosing finishing supplies, it is crucial to consider not just the effectiveness, but also the compliance of products with health and environmental standards.

Which abrasives are best suited for different metalworking tasks?

When choosing abrasives for different metalworking tasks, consider the following guidelines to select the most suitable materials:

Aluminum Oxide: Ideal for general-purpose metal grinding, it's effective on iron and steel and is a cost-effective option.

Silicon Carbide: Best for harder metals like brass, aluminum, and titanium due to its harder and sharper quality.

Different tasks require varying grit sizes:

24-60 Grit: Suitable for rough grinding to remove material quickly.

80-180 Grit: Used for intermediate machining to balance between material removal and surface finish.

220 and Higher Grit: Perfect for fine finishing and polishing to achieve a smooth surface.

For high-stress applications:

Ceramic Abrasives: Durable and remain sharp for longer durations, excellent for rigorous grinding.

Zirconia Alumina: Particularly good for heavy-duty material removal on steel and stainless steel.

Always ensure that your selection aligns with current health and environmental standards, including REACH regulations in the EU, to guarantee safety and compliance in your metalworking projects. For further assistance and information on REACH compliance, you can explore resources provided by the European Chemicals Agency.

What are the benefits of selecting the right grit size in metal finishing?

The benefits of selecting the right grit size in metal finishing are crucial for achieving the desired surface finish, efficient material removal, and the longevity of your tools. Here are the key advantages:

Surface Finish Quality: Using the correct grit size ensures that you can reach the desired level of smoothness or texture on the metal surface. Fine grits are used for a smooth, polished finish, whereas coarser grits are needed for rapid material removal and initial shaping.

Project Efficiency: The right grit can substantially increase the efficiency of your work. A grit that is too fine may take excessively long to remove material, while one that is too coarse can damage the workpiece or remove too much material too quickly.

Tool Longevity: Matching the grit to the metal and the task can help prevent excessive wear on your tools. This proper match ensures that abrasives are used within their intended capacities, which can extend the life of these expensive supplies and reduce the need for replacements.

To maintain compliance and safety, it's essential to ensure that your metal finishing processes adhere to guidelines such as those stipulated by the REACH regulation, which aims at the safe management of chemicals in the industry. Visit the European Chemicals Agency for more info on compliance.

How do different coatings and sealants enhance the longevity and aesthetics of metal projects?

Different coatings and sealants enhance the longevity and aesthetics of metal projects by offering varied degrees of protection against environmental elements, mechanical wear, and corrosion. Here are some key benefits:

Corrosion Resistance: Coatings like epoxy provide a barrier against moisture and chemicals that can cause rust and corrosion.

Aesthetic Appeal: Finishes like clear lacquer or powder coatings not only protect but also enhance the look of a metal item, offering a range of colors and gloss levels.

Surface Durability: Using sealants can strengthen the surface, making it more resistant to scratches, abrasion, and temperature variations.

Always ensure that the products used comply with safety and environmental regulations such as REACH, and consult safety data sheets for handling and application guidance.

What tools are essential for achieving a professional finish in metalworking and smithing?

To ensure a professional finish in metalworking and smithing, it's essential to use finishing supplies that comply with health and environmental regulations such as REACH to ensure safety and sustainability. Aspiring professionals must be acquainted with these regulations, which include:

Chemical Compliance: All chemical substances must conform to REACH's requirements to ensure the safe handling and management of chemicals in the workplace.

Substance Authorization: Only authorized chemicals under REACH should be used in finishing processes, reinforcing the obligation for safe practice.

Hazard Classification: Supplies should be correctly labeled and classified, as mandated by CLP regulations, to prevent misuse and foster safety.

Moreover, an awareness of the specific properties and appropriate applications of various abrasives, such as aluminum oxide, silicon carbide, and zirconia alumina, can have a profound impact on achieving the desired finish. Additionally, the correct choice and application of coatings and sealants, including clear lacquer, epoxy coatings, and powder coating, are critical for prolonging the lifespan and enhancing the aesthetics of metalwork.

In terms of tools, having precision tools such as spatulas, X-Acto knives, deburring tools, pliers, sandpapers, digital calipers, tweezers, hex keys, and screwdrivers is important for fine-tuning and securing metal components. Temporary adhesion solutions like glue sticks and masking tape can assist with assembly and finishing tasks.

Finally, professionals must take safety precautions seriously by using appropriate PPE, venting workspaces, properly handling and storing chemicals, and following emergency and disposal procedures in compliance with local regulations.

These combined efforts not only result in high-quality finished metal products but also promote a safe and compliant working environment. For the latest guidelines on REACH compliance and safety measures, professionals should consult resources provided by organizations like the European Chemicals Agency and the Department of Toxic Substances Control.