Essential Welding Supplies for Blacksmith Projects

Abana Chapter

February 09, 2024

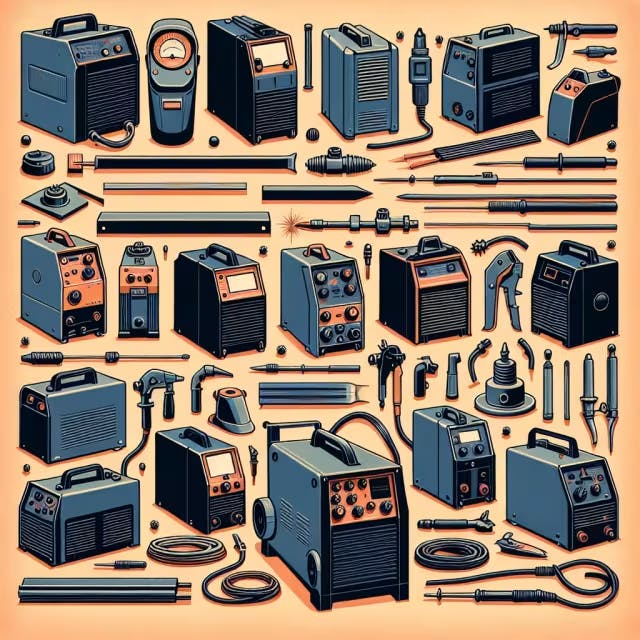

Welding, an indispensable fabrication technique, has evolved from its primitive roots in blacksmith projects to become a cornerstone in modern construction and repair. This meticulous process, essential in joining metals or thermoplastics through the application of intense heat, has transcended simple forge welding to embrace advanced methods fueled by technological progress and industrial demands. With a significant array of welding supplies and equipment required for various projects, understanding the essential welding supplies for blacksmith projects is fundamental for anyone looking to venture into or excel in this skilled trade.

Key Takeaways

Understanding the various supplies and their functions is crucial for effective welding in blacksmith projects.

Choosing the appropriate welder is fundamental to achieving desired results in blacksmithing.

Investing in protective gear is essential for ensuring the safety of the welder during the welding process.

Essential welding accessories can significantly enhance efficiency and precision in welding tasks.

Regular maintenance of welding equipment is key to ensuring its longevity and performance.

Understanding Welding Supplies and Their Functions

Welding plays a pivotal role in blacksmith projects, merging metal pieces with precision and strength. The right supplies are crucial for quality results. Here’s a quick guide:

Welding Machine: The heart of your setup, available in different types such as MIG, TIG, and Stick welders. Each caters to specific metal types and thicknesses.

Welding Helmet: Safety first. A good helmet protects your eyes from harmful light and your face from sparks.

Gloves and Protective Clothing: Heat-resistant gloves and clothing shield against burns and ultraviolet radiation.

Welding Rods/Electrodes: These consumables must match the metal type you're working with to ensure a strong bond.

For more detailed guidance on selecting the right welding machine and safety gear for your blacksmithing projects, check out this comprehensive guide.

Remember, quality tools lead to quality craftsmanship in your blacksmith projects. Always invest in reliable supplies to bring your metal creations to life safely and effectively.

Selecting the Right Welder for Blacksmithing

When delving into the world of blacksmithing projects, choosing the correct welding equipment is paramount for both the quality and safety of your work. A welder that suits your project needs ensures that you can confidently tackle any task at hand.

Types of Welders:

MIG Welders: Ideal for beginners due to their ease of use. They work well with a variety of metals and thicknesses, making them versatile for different projects.

TIG Welders: Best suited for projects requiring precision and finesse. They offer greater control over the weld, perfect for detailed work.

Stick Welders: These are more adaptable to outdoor conditions and can handle rusty or dirty metals. Though they require more skill, they’re invaluable for heavy-duty repairs.

Deciding which welder to use depends on factors including the type of metal, thickness, and the specific requirements of the blacksmith project you're working on. For instance, TIG welding allows for the intricate joining of metals, making it a popular choice for customization projects that require detailed workmanship.

Choosing the right welding supplies also extends beyond the welder itself. For a comprehensive blacksmith project toolkit, include:

Auto-darkening Welding Helmet: Protects eyes and face while providing a clear view of the weld.

Welding Gloves: Essential for hand protection against heat and sparks.

Metal Brush and Hammer: For cleaning the weld area and removing slag post-weld.

By selecting the right tools and equipment, you ensure a smoother workflow and higher quality results in your blacksmithing endeavors. Each piece of equipment plays a critical role in the crafting process, from the precision of your welds to ensuring your safety and comfort throughout the project.

Protective Gear for Safe Welding

Welding safely requires the right protective gear, especially for blacksmith projects where high temperatures and sparks are involved. A comprehensive setup includes several critical items:

Welding Helmet: Protects eyes and face from ultraviolet and infrared rays, sparks, and debris. Opt for an auto-darkening helmet for ease of use.

Fire-Resistant Clothing: Helps shield the body against burns from sparks and slag. A welding jacket or apron made from leather or flame-retardant materials is advisable.

Gloves: Thick, durable gloves designed specifically for welding offer protection against heat, sparks, and sharp objects. Leather gloves provide the best mix of durability and flexibility.

Safety Glasses: Worn under the welding helmet for an additional layer of protection against flying particles.

Respirator: Essential for ventilating harmful fumes, especially in confined spaces.

Ear Protection: Protects against noise from welding equipment and hammering in blacksmithing projects.

For those looking to dive into blacksmith projects, ensuring you're outfitted with these supplies is crucial for safety and success. Each item plays a significant role in safeguarding against common welding hazards, making them indispensable for both beginners and seasoned professionals. Opting for quality gear not only ensures better protection but can also enhance comfort and efficiency on the job.

Essential Welding Accessories for Efficiency

Blacksmith projects often require precision and efficiency, making the right welding accessories crucial. A well-prepared workspace includes various tools and equipment designed to enhance welding techniques and ensure safety.

Auto-darkening Welding Helmet: Protects eyes from harmful rays, with the auto-darkening feature allowing for clear visibility before and during welding.

Welding Gloves: Essential for hand protection against heat, sparks, and spatter.

MIG Pliers: Multi-functional tool for wire cutting, nozzle and tip removal, and spatter cleanup.

Chipping Hammer and Wire Brush: For slag removal and cleaning the weld area before and after welding.

Incorporating these essential welding supplies can significantly improve the quality of blacksmithing projects by ensuring precise joins and clean finishes. Remember, selecting quality tools not only increases the efficiency of your projects but also adds to the longevity of your equipment.

Maintaining Your Welding Equipment for Longevity

Ensuring the longevity of your welding supplies is crucial for successful blacksmith projects. Regular maintenance not only extends the life of your equipment but also ensures safety and efficiency. Here are some tips:

Clean Equipment Regularly: Dust and residue can accumulate on your welding gear, causing it to malfunction or deteriorate faster. Use a clean cloth to wipe down your welding machine and accessories after each use.

Inspect Cables and Connections: Before starting any welding project, check all cables and connections for wear and tear. Replace any frayed or damaged cables immediately to prevent accidents and ensure optimal performance.

Store Supplies Properly: When not in use, store your welding supplies in a clean, dry place. Moisture can cause rust and degradation, especially on metal surfaces and components.

Regularly Check Gas and Consumables: For gas welding equipment, regularly check the levels and quality of gas. Also, keep an eye on your stock of consumables like tips and rods, replacing them as needed to avoid mid-project shortages.

Follow Manufacturer’s Instructions for Maintenance: Each piece of equipment may have specific maintenance requirements. Always refer to the manufacturer’s guidelines for the best care practices.

By following these maintenance tips, you can greatly extend the life of your welding supplies, ensuring that they remain reliable and effective for your blacksmith projects. In conclusion, having the right welding supplies is fundamental for achieving success in blacksmith projects. By carefully selecting appropriate welders, protective gear, and accessories while adhering to a strict maintenance routine, blacksmiths can ensure both their safety and the longevity of their equipment. Ultimately, investing in essential welding supplies not only enhances efficiency and the quality of the work but also fosters a safer working environment.

Frequently Asked Questions

What are the essential welding supplies needed for successful blacksmith projects?

For successful blacksmith projects, essential welding supplies include a Welding Machine (MIG, TIG, or Stick depending on the project's specifics), Auto-darkening Welding Helmet, Heat-resistant Gloves and Protective Clothing to shield against burns and UV radiation, and Welding Rods/Electrodes tailored to the metal type you're working with. Incorporating tools like MIG Pliers, Chipping Hammer, and Wire Brush for cleanup and prep further enhances the quality of your work. Regular maintenance of your equipment, including cleaning, inspecting cables, proper storage, and adherence to manufacturer maintenance guidelines, ensures safety, efficiency, and longevity of your tools. These supplies, combined with careful selection and upkeep, form the foundation for high-quality craftsmanship in blacksmithing.

How do I choose the right welding machine for my blacksmith project?

Choosing the right welding machine for your blacksmith project involves understanding the nature of your project and selecting equipment that matches those requirements. Consider the following key points:

For versatility and ease of use, especially for beginners, MIG Welders are recommended. They are well-suited for various metals and thicknesses.

If your project demands precision and detailed work, TIG Welders are ideal due to their superior control during welding.

For outdoor conditions or projects involving rusty or dirty metals, Stick Welders are advantageous due to their adaptability.

Additionally, ensure you have the appropriate safety gear, including an auto-darkening welding helmet, heat-resistant gloves, and protective clothing, to safeguard against potential hazards. Regular maintenance of your welding machine and accessories is crucial for both longevity and performance. Always invest in quality tools to achieve the best results in your blacksmithing ventures.

Why is protective gear crucial for welding in blacksmith projects, and what are the essentials?

Protective gear is critical for welding in blacksmith projects due to the high risk of burns, ultraviolet radiation exposure, and inhalation of harmful fumes. The essentials include:

Welding Helmet: An auto-darkening helmet offers protection from harmful light rays and sparks, enhancing both safety and welding precision.

Gloves and Protective Clothing: Heat-resistant gloves and clothing made from leather or flame-retardant materials protect against heat, sparks, and UV radiation.

Safety Glasses and Respirator: Safety glasses provide an additional layer of protection under the helmet for the eyes, while respirators are crucial for ventilating harmful fumes, especially when working in confined spaces.

Ear Protection: To guard against the high-decibel noise from equipment and hammering, which is commonplace in blacksmith projects.

Investing in quality protective gear not only ensures safety but also improves the efficiency and quality of welding work within blacksmith projects.

How can I ensure the longevity and maintenance of my welding supplies for blacksmith projects?

Ensuring the longevity and maintenance of your welding supplies for blacksmith projects involves regular care and proper storage. Here are key tips:

Clean your equipment regularly to prevent dust and residue buildup that can lead to malfunctions or premature deterioration. Use a clean cloth for wiping down your welding machine and accessories.

Inspect cables and connections for signs of wear and tear before each use, replacing any that are frayed or damaged to ensure safety and optimal performance.

Store your supplies in a clean, dry place to avoid rust and degradation, especially crucial for metal surfaces and components.

Regularly check gas levels and consumables like tips and rods for gas welding equipment, replacing as necessary to avoid running out mid-project.

Follow the manufacturer’s maintenance instructions specifically designed for each piece of your welding equipment for the best care practices.

Adhering to these maintenance steps can significantly prolong the life and efficiency of your welding supplies, keeping them ready and reliable for your blacksmithing projects.

What additional welding accessories should be considered to enhance blacksmithing projects?

In enhancing blacksmithing projects with additional welding accessories, consider integrating:

Auto-darkening Welding Helmet: For superior eye and face protection that adjusts to light conditions automatically, allowing for better visibility and precision.

Welding Gloves: Heat-resistant and durable, they safeguard your hands from burns and injuries.

MIG Pliers: A versatile tool for various tasks including wire cutting and spatter cleanup, crucial for maintaining a clean work area.

Chipping Hammer and Wire Brush: Essential for removing slag and cleaning the weld area, ensuring strong, clean welds.

Maintaining these tools through regular cleaning, inspecting cables and connections for wear, storing supplies properly, checking gas levels and consumables, and following manufacturer’s maintenance instructions will ensure the longevity and reliability of your equipment. These practices not only enhance the quality of your projects but also promote a safer working environment.