Durable Swage Blocks for Blacksmithing Projects

Abana Chapter

February 05, 2024

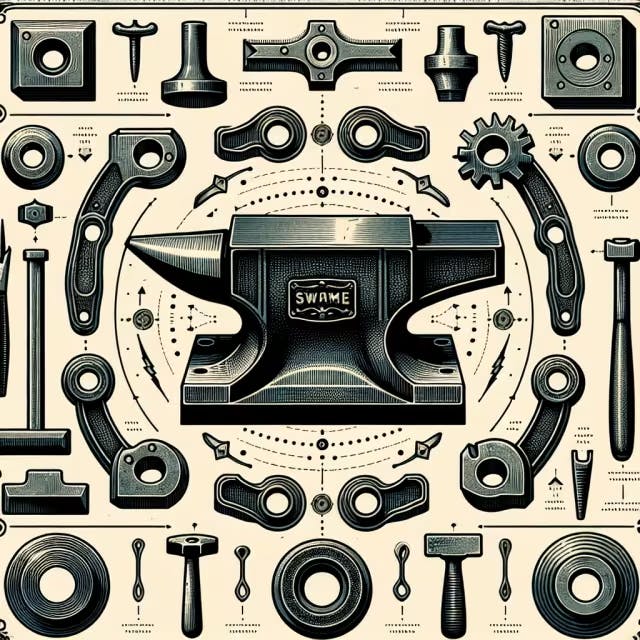

In the dynamic arena of blacksmithing, equipping yourself with the right tools is critical to the success of any project. Among these, durable swage blocks for blacksmithing projects emerge as the unsung heroes, providing versatility and precision to the hands that skillfully shape metal. Understanding the integral role these robust, multipurpose tools play, our deep dive explores materials that withstand the test of time, key characteristics of top-tier swage blocks, and how selecting and maintaining the ideal one can amplify the quality of your craftsmanship.

Key Takeaways

Swage blocks are critical, versatile tools in blacksmithing that aid in precision and add versatility to metal shaping.

The best materials for swage blocks are those that can withstand repeated use over time without significant wear.

High-quality swage blocks have key characteristics such as impact resistance, heat tolerance, and a variety of shapes and sizes for different tasks.

Selecting the right swage block involves considering the specific requirements of your blacksmithing projects and how the block's features align with those needs.

Proper maintenance of swage blocks is essential for their longevity, and this includes regular cleaning, correct storage, and timely repair of any damage.

Investing in a durable swage block and maintaining it well will significantly enhance the quality and efficiency of your metalworking endeavors.

Understanding Swage Blocks in Blacksmithing

Swage blocks are an indispensable tool for blacksmiths, providing a solid foundation for shaping and processing metal. These versatile blocks feature various shapes like rounds, squares, and ovals, making them multi-functional for different blacksmithing techniques. When selecting a swage block, durability is paramount as it directly impacts the quality and longevity of both the tool and the projects it helps create.

Material | Properties | Durability | Applications |

Cast Iron | Affordable, Heavy | Moderate | General Blacksmithing |

Steel | High Strength, Pricier | High | Professional Workshops |

High-quality swage blocks, often made from ductile iron or high carbon steel, provide increased resistance to wear and chipping, ensuring that each investment contributes to countless successful projects. Blacksmiths looking for top-grade tools often gravitate towards reputable manufacturers who employ rigorous standards to craft these essential items.

One such example of durability and craftsmanship can be found with swage blocks created by Centaur Forge, a trusted supplier within the blacksmith community. By using such reliable resources, blacksmiths can rest assured that their swage blocks withstand the rigors of metal forging, making them a valuable addition to any workshop.

The Best Materials for Durable Swage Blocks

Selecting the right material for your swage block directly impacts the tool's durability and your project's outcome. Experienced blacksmiths often recommend high-grade cast iron for its supreme durability and resilience under repeated high-impact use. This material resists wear and is less likely to deform under the hammer’s blow, ensuring a long service life.

Another popular option is cast steel. Known for its toughness, it effectively withstands the demanding conditions of metal shaping and forming. Although typically more expensive than cast iron, its longevity can justify the investment. Here are two durable materials suitable for swage blocks, each offering distinct benefits for blacksmithing projects:

Material | Pros |

Cast Iron | Durable, cost-effective, excellent at resisting wear |

Cast Steel | Exceptionally tough, long-lasting, withstands high-impact use |

For those seeking a more affordable solution, certain alloys designed for high-impact resistance can serve as suitable substitutes though they may not achieve the longevity of cast iron or steel. Always consider the types of projects you undertake, as materials like aluminum might be suitable for softer metals but not ideal for heavy forging.

When purchasing a swage block, assess the alloy composition and heat treatment process, as these factors are pivotal in determining the block's durability. Reputable suppliers provide detailed specifications that help in making an informed choice. To ensure you select a swage block that meets your quality standards and suits your unique blacksmithing need, visit specialized stores or trusted online platforms where professionals source their equipment.

Essential Features of High-Quality Swage Blocks

When selecting swage blocks for blacksmithing projects, the material composition is a primary consideration. High-grade cast iron or steel swage blocks ensure longevity and resistance to wear, even under rigorous forging conditions. The complex array of holes and depressions should be finely machined for precision work, catering to a variety of shapes and sizes of metalwork. The surface finish is also crucial as it prevents the metal from snagging, ensuring a smooth workflow.

Moreover, weight and portability factor into the decision-making process, especially for those who need to transport their tools to various work sites. Heavier swage blocks provide more stability for heavy-duty work, while lighter models may be preferable for more intricate or less forceful tasks.

As trends and technology continue to evolve, so do the standards and expectations for these tools. For the most current selection of durable swage blocks that meet the needs of modern blacksmiths, Centaur Forge offers a comprehensive catalog that reflects the quality and variety demanded by the trade.

Feature | Benefit |

Material Composition | Durability and resistance to wear |

Finely Machined Depressions | Precision for various metal shapes |

Surface Finish | Smooth workflow and metal protection |

Weight | Stability for heavy-duty work or portability for light tasks |

Current Selection | Meets modern blacksmithing standards |

Acquiring a swage block that possesses these attributes ensures a valuable investment in your blacksmithing toolkit, facilitating the creation of exceptional metal pieces with both efficiency and ease.

Choosing the Right Swage Block for Your Blacksmithing Project

When selecting a swage block for your blacksmithing endeavors, material composition is paramount for endurance and functionality. Cast iron swage blocks, renowned for their durability, are a preferred choice for many. Opt for those treated for increased resistance to wear and thermal shock to ensure they withstand repetitive heating and hammering. Size and weight play a crucial role as well; a block that is too small may not accommodate larger projects, while an excessively heavy block can be problematic to reposition.

Consider the array of shapes and cavities featured on the block. A diverse selection of depressions allows for more versatility in shaping metal. Standard shapes include V and U troughs, round and square holes, and edges for bending. Gauging the frequency and scope of use will help you determine the level of investment needed. Professional-grade swage blocks deliver greater longevity but they come with a higher price tag, making them suitable for those who require robust equipment for frequent, heavy-duty work.

To elucidate, here's a quick-reference table highlighting key features to look for:

Feature | Description |

Material | Preferably cast iron for maximum durability |

Size & Weight | Must be manageable yet sufficient for project scales |

Shape Diversity | Look for multiple depressions for versatility |

Investment Level | Corresponds with usage frequency and project complexity |

For the latest, high-quality blacksmithing tools, browse reputable suppliers with a proven track record in supplying durable swage blocks for blacksmithing projects. Remember, a well-crafted swage block is a one-time investment that significantly impacts the quality and efficiency of your blacksmithing work.

Maintenance Tips for Long-Lasting Swage Blocks

Caring for swage blocks is crucial to ensure their longevity and reliability in blacksmithing. Regularly cleaning them after use to remove scale and debris will prevent pitting and deterioration. Applying a light coating of oil can ward off rust, especially in humid environments. Store your swage block in a dry area when not in use to further impede rust formation.

Maintenance Tip | Benefit |

Clean after each use | Prevents accumulation of scale and debris |

Light oil application | Protects against rust and corrosion |

Dry storage location | Keeps moisture away, reducing rust risk |

Despite their robust nature, avoid dropping your swage block or subjecting it to unnecessary impact, as this can cause chips or cracks. Should any surface irregularities appear over time, addressing them promptly will prevent worsening damage that could compromise the tool's effectiveness. As blacksmiths often say, a well-maintained swage block is as essential to the forge as the anvil itself. For insightful recommendations on selecting and preserving these tools, check out industry expert advice. Remember, a swage block treated with care is an investment in the quality and efficiency of your blacksmithing projects. In conclusion, choosing durable swage blocks for blacksmithing projects is essential for achieving precision and efficiency in your craft. The critical selection of high-grade materials and regular maintenance ensures that these tools withstand the demands of repetitive use and thermal stress. By investing in quality products from trusted suppliers and adhering to proper care techniques, blacksmiths can ensure that their swage blocks remain reliable and effective for years to come.

Frequently Asked Questions

What are the best materials for durable swage blocks in blacksmithing projects

Among the most reliable materials for durable swage blocks in blacksmithing are high-grade cast iron and cast steel, both known for their exceptional strength and longevity in the face of heavy and repetitive use. Cast iron is appreciated for its wear resistance and cost-effectiveness, making it a standard choice for a variety of general blacksmithing jobs. In contrast, cast steel, while more expensive, offers higher toughness and is suitable for professional blacksmithing environments that demand high-impact resistance. It's important to select a block with a material and size appropriate for the intended tasks and to ensure it comes from a reputable supplier like Centaur Forge, which adheres to strict quality standards.

How can the material choice impact the quality of blacksmithing work

The material choice for a swage block significantly impacts the quality of blacksmithing work, affecting durability, the ability to resist wear, and the overall longevity of the tool. Cast iron is a durable, cost-effective option that excels at resisting wear, making it a good choice for general blacksmithing. Alternatively, cast steel offers exceptional toughness and can withstand the demanding conditions of professional workshops, providing a long-lasting solution for high-impact use. Regardless of the choice, professional blacksmiths tend to opt for swage blocks made from high-grade materials which are less prone to deformation from the hammer’s blows, ensuring precision work over a significant period. Maintenance is also crucial, with regular cleaning and storage in dry conditions extending the swage block’s life and preserving its functionality for crafting quality metal pieces.

What are the benefits of selecting a cast iron swage block over other materials

The selection of a cast iron swage block comes with several benefits:

Durability: Cast iron is known for its longevity and resistance to wear, which is crucial for blacksmithing tasks that often involve high-impact use.

Cost-effectiveness: Compared to other materials like steel, cast iron swage blocks are generally more affordable, making them a practical choice for both beginners and seasoned blacksmiths.

Resistance to Deformation: Under repeated use and the hammer's blow, cast iron maintains its shape, ensuring the swage block remains a reliable tool for shaping metal over a long period.

While steel swage blocks offer exceptional toughness and a longer lifespan, they come at a higher cost. However, the investment in a cast iron swage block can be a wise balance of cost and durability, especially for general blacksmithing needs. For those who require a tool that endures through numerous projects while keeping expenses in check, cast iron is an ideal option.

How does the size and variety of depressions on a swage block affect its versatility

The size and variety of depressions on a swage block greatly enhance its versatility by providing blacksmiths with the ability to perform multiple metalworking tasks using a single tool. Larger swage blocks with diverse depressions allow blacksmiths to work on a wider range of project sizes, from small detailed pieces to larger metal forms. The various shapes and sizes of the depressions, such as round, square, V and U troughs, and specialized edges, enable the tool to be used for different techniques, including shaping, sinking, and bending metal.

Where can blacksmiths find high-quality swage blocks that withstand rigorous forging

High-quality swage blocks can be sourced from reputable blacksmithing supply companies like Centaur Forge. It's important to select swage blocks made from durable materials like high-grade cast iron, which is cost-effective and resistant to wear, or cast steel, known for its toughness and capability to withstand high-impact use. Forged from such materials, swage blocks are invaluable for a diverse range of blacksmithing applications, from general work to professional workshops, ensuring both the tool's longevity and the quality of finished metal projects.

What are essential care tips for maintaining the durability of swage blocks in blacksmithing

Caring for swage blocks is crucial to ensure their longevity and reliability in blacksmithing. Regularly cleaning them after use to remove scale and debris will prevent pitting and deterioration. Applying a light coating of oil can ward off rust, especially in humid environments. Store your swage block in a dry area when not in use to further impede rust formation.

Maintenance Tip | Benefit |

Clean after each use | Prevents accumulation of scale and debris |

Light oil application | Protects against rust and corrosion |

Dry storage location | Keeps moisture away, reducing rust risk |

Despite their robust nature, avoid dropping your swage block or subjecting it to unnecessary impact, as this can cause chips or cracks. Should any surface irregularities appear over time, addressing them promptly will prevent worsening damage that could compromise the tool's effectiveness. As blacksmiths often say, a well-maintained swage block is as essential to the forge as the anvil itself. For insightful recommendations on selecting and preserving these tools, check out industry expert advice. Remember, a swage block treated with care is an investment in the quality and efficiency of your blacksmithing projects.