Belt Sanders and Abrasives for Metal Finishing

Abana Chapter

February 05, 2024

When it comes to achieving a flawless finish in metalworking, the combination of belt sanders and the right abrasives cannot be overstated. If you're looking to enhance the quality of your metal finishing projects, understanding the intricacies of these tools and materials is indispensable. This article will guide you through the selection and use of belt sanders and abrasives, ensuring that you approach your metal finishing with confidence and finesse.

Key Takeaways

Belt sanders are crucial tools for achieving a flawless finish in metalworking, and selecting the appropriate one for your project is essential.

The right abrasives must be chosen based on the specific requirements of your metal projects to ensure quality and precision.

Employing proper sanding techniques can significantly affect the outcome of the metal finishing process.

Regular maintenance and adherence to safety guidelines are imperative to extend the lifespan of belt sanders and to protect users.

Innovative abrasive solutions can enhance metal finishing, offering better performance and potentially reducing work time.

Understanding the interplay between belt sanders, abrasives, and techniques is key to achieving the desired finish in metalworking crafts.

Understanding Belt Sanders for Metal Finishing

Belt sanders are power tools that make quick work of shaping and finishing metal surfaces. They are fitted with abrasive belts designed to tackle different grades of metal work efficiently. The belts continuously rotate on two drums, which allows for the consistent sanding action necessary for even finishes. Here is a brief overview of factors to consider when selecting a belt sander and abrasive materials for metal finishing tasks.

Feature | Consideration |

Belt Size | Larger belts cover more surface area but may be less maneuverable. |

Motor Power | Higher amperage ensures that the sander can handle tougher jobs. |

Speed Settings | Variable speed provides more control for different types of metal. |

Ergonomics | Look for models with comfortable grips and balanced weight distribution. |

Choosing the appropriate abrasive type is crucial for achieving the desired finish. Zirconia alumina and ceramic abrasives are popular choices for metalwork, providing long-term durability and consistent results. Check for belts designed to dissipate heat well to prevent the metal from warping during the sanding process.

To better understand the full potential of these tools when working with metal, you might want to read insights from industry experts, such as those shared in recent online articles. Always ensure that you invest in quality abrasives that match the metal type you're working with, such as finer grits for getting a smooth surface on soft metals or coarser grits for shaping harder metals. Safety should also be a priority; be sure to follow the manufacturer’s instructions and use the appropriate personal protective equipment (PPE) when operating belt sanders.

Choosing the Right Abrasives for Your Metal Projects

Selecting the appropriate belts and abrasives for metal finishing can be a pivotal choice that affects the quality and efficiency of your work. To strike the right balance between removal rates, finishes, and lifespan, consider the following factors:

Abrasives Factor | Consideration |

Grit Size | Coarser grits remove material faster but leave a rougher finish. Finer grits are for final finishing and achieving smoother surfaces. |

Material | Zirconia and ceramic grains are durable and suited for aggressive metal removal. Aluminum oxide is a versatile, economical choice for general metal work. |

Backing Material | Cloth-backed belts are more durable and suitable for heavy-duty applications, while paper-backed abrasives are used for lighter-finishing tasks. |

Belt Size | Ensure compatibility with your belt sander for optimal performance. |

Opt for reputable brands in abrasives that offer consistent quality, as lesser-known brands may have irregularities that lead to uneven finishes or shortened belt life. When choosing belts for your belt sander, bear in mind the type of metal you're working with—stainless steel may require different abrasives compared to softer metals like aluminum. This targeted approach not only ensures a superior finish but also extends the life of your abrasives.

Additionally, remember that heat buildup can damage the workpiece and shorten the life of your abrasive. Some belts are engineered with cooling properties, which can be a critical aspect when working on heat-sensitive metals or high-speed operations.

Safety should also be a priority. Wear proper protective equipment and ensure your equipment is appropriately maintained to prevent any workplace accidents. Regularly inspect your belts for any signs of wear or damage. Taking these considerations into account will help you achieve optimal results in your metalworking projects.

The Importance of Proper Sanding Technique

When utilizing belt sanders and abrasives for metal finishing, the sanding technique plays a vital role in achieving the desired outcome. A well-executed sanding process ensures that paint adheres properly and contributes to an even finish, minimizing potential issues such as peeling or flaking. Especially when dealing with glossy surfaces, sanding before paint application is crucial as it provides a more receptive bonding surface, ultimately reducing future complications.

Selecting the appropriate sandpaper granularity is also important. Fine-grit sandpaper, for example, is recommended to create the necessary microscopic grooves that promote better adherence, as noted by experts at Pristine Painters NYC. While not all surfaces may require sanding, such as some higher-end paints or pre-treated materials, certain situations, including the application of cheaper paints, raw wood surfaces, or polyurethane, call for sanding to prevent brush marks and poor adhesion.

Surface Condition | Sanding Requirement | Grit Recommendation |

Raw Wood | Yes | Medium to Fine |

Previous Paint Job | Dependent on Finish | Fine to Very Fine |

Glossy Surface | Yes | Fine to Ultra Fine |

Proper preparation, including cleaning and sanding, is essential to obtain a lasting, high-quality finish. Effective technique and the right abrasives can make all the difference in metal finishing projects.

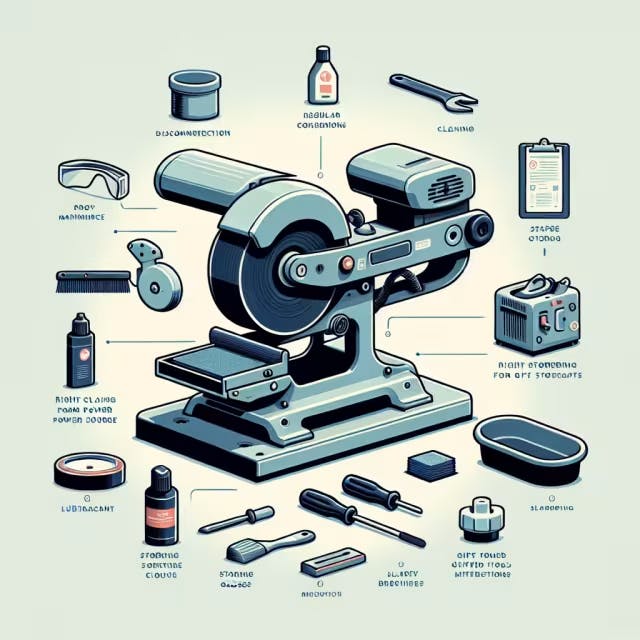

Belt Sander Maintenance and Safety Tips

Regular upkeep of your belt sander ensures optimal performance and prolongs its lifespan. Begin by regularly checking the belt for wear and tear; replace it if you notice any significant damage or wear. Monitor the tracking of the belt as well, making certain the belt stays centered during use to avoid uneven abrasion or potential hazards. Dust accumulation can affect your sander's efficiency, so it's vital to clean vents and component parts to prevent buildup. Utilize compressed air or a vacuum to remove debris from hard-to-reach places.

Safety measures are equally crucial when operating belt sanders. Always wear appropriate personal protective equipment, including safety glasses and hearing protection, to guard against flying particles and loud noise. Never remove the machine guards that are designed to protect you from moving parts and ensure you are working in a well-ventilated area to avoid inhaling metal filings and dust.

Here's a quick table to sum up the key points:

Maintenance Task | Frequency |

Inspect and replace belt | Before each use/as necessary |

Check belt tracking | Weekly/during use |

Clean dust from vents/parts | After every use |

Safety Measures | |

Wear protective equipment | During use |

Keep guards in place | Always |

Work in a ventilated area | Always |

For anyone who uses these tools, following these guidelines and performing routine checks can be the difference between a precision finish and a compromised project. Keep in mind that an ounce of prevention is worth a pound of cure, especially when it comes to high-powered tools like belt sanders. For more details on belt sander maintenance and safety, don't hesitate to consult your tool's manual or reach out to the manufacturer for specific guidance.

Innovative Abrasive Solutions for Enhanced Metal Finishing

Belt sanders and abrasives are indispensable tools for any metalworking project, offering superior results in metal finishing. Selecting the right abrasive belt material is crucial to achieving the desired surface finish, longevity, and efficiency. Aluminum oxide, for instance, is a popular choice for general metalwork due to its durability and affordability.

For more demanding tasks, zirconia abrasives are renowned for their aggressive cutting action and heat resistance, making them suitable for heavy stock removal. When working with stainless steel or high-temperature alloys, ceramic grit is favored for its exceptional hardness and fast-cutting properties.

To optimize the finishing process, metalworkers should consider the following additional factors:

Grit Size: Coarser grits remove more material quickly but leave a rougher finish. Finer grits are best for creating a smooth, polished surface.

Belt Speed: High-speed sanding can deliver quick results, but may also produce more heat and potentially warp the metal.

Machine Power: Higher horsepower sanders can handle tougher jobs without bogging down.

While belt sanders significantly expedite the finishing process, it's the synergistic effect of the machine with the right kind of abrasive that truly perfects the workpiece. Harnessing advancements in abrasive grain technology and backing materials can also impact performance.

For example, newer ceramic alumina belts have been designed to last significantly longer than traditional materials. Below is a simplified chart that highlights common abrasive types and their typical applications:

Abrasive Type | Primary Use |

Aluminum Oxide | General metalworking |

Zirconia | Heavy stock removal and rough shaping |

Ceramic | High-stress grinding on tough alloys |

As technology evolves, so too does the selection of belt sanders and abrasives geared toward metal finishing, offering ever-improving results for metalworkers of all skill levels. For in-depth comparisons and the latest product offerings, visiting specialized metalworking suppliers can provide valuable insights. In conclusion, selecting the right belt sander and abrasive for your metal finishing project is a critical decision that impacts the quality, efficiency, and safety of your work. By understanding the nuances of various sanders and abrasives, and implementing proper sanding techniques alongside regular maintenance, craftsmen can ensure a professional and durable finish. Regardless of your project's scale or complexity, investing in suitable tools and applying the knowledge shared will enhance your metal finishing results.

Frequently Asked Questions

What are the key considerations when selecting a belt sander for metal finishing?

When selecting a belt sander for metal finishing, important considerations include:

Belt Size: Larger belts cover more surface area but may be less maneuverable. Smaller belts might be more suitable for detailed work or smaller pieces.

Motor Power: A higher amperage motor ensures that the sander can handle more challenging tasks and tougher metals more effectively.

Speed Settings: Having variable speed control can give you more versatility to work with different types of metal and finishes.

Ergonomics: Comfortable grips and balanced weight distribution can reduce user fatigue and improve control during long sanding sessions.

Regarding abrasive belts:

Grit Size: Choose coarser grits for rapid material removal and shaping, while finer grits provide a smoother finish for final touches.

Material: Zirconia alumina and ceramic abrasives are durable options for aggressive metal removal, while aluminum oxide is a good all-purpose choice.

Backing Material: Cloth-backed belts offer durability for heavy-duty use, whereas paper-backed belts may be more suitable for finer, lighter finishing tasks.

Heat Dissipation: Belts that dissipate heat effectively are crucial to prevent warping the metal, especially during prolonged use.

Always invest in high-quality abrasives that correspond with the metal you're working on. Safety should be a priority; use appropriate personal protective equipment and follow the manufacturer’s guidelines while operating belt sanders. For a deeper understanding of belt sanders, consider consulting recent online articles from industry experts.

How do you choose the right abrasive material for your metalworking project?

Selecting the right abrasive material for a metalworking project involves considering the type of metal, the desired finish, and the specific requirements of the task at hand. To ensure you choose the appropriate abrasive, keep in mind the following points:

Grit Size: Decide between coarser grits for rapid material removal and a rough finish, or finer grits for smooth finishing.

Material: Aluminum oxide is good for general metalwork, zirconia is excellent for aggressive cutting and heat resistance, and ceramic grit is best for hard, high-temperature alloys.

Belt Size: Match the belt size to your sander for optimal performance and surface coverage.

Machine Power and Belt Speed: High-powered and high-speed sanders are great for tough jobs but monitor heat buildup that could warp the metal.

Heat Dissipation: Use belts that are engineered to dissipate heat, extend their life, and protect the workpiece.

Choose reputable brands known for their quality and match the abrasive to the metal you are working with; for instance, stainless steel may require different abrasives compared to softer metals like aluminum. Additionally, follow safety guidelines and wear appropriate PPE when operating belt sanders. For more detailed information, industry insights from resources like This Old House and 3M can help guide your selection of belt sanders and abrasive materials.

What are the benefits of using zirconia alumina and ceramic abrasives in metal finishing

Zirconia alumina and ceramic abrasives offer several benefits for metal finishing:

Durability: Both zirconia alumina and ceramic grains are incredibly durable, making them ideal for aggressive material removal and long-term use.

Efficiency: These abrasives provide efficient stock removal rates and maintain their cutting edge as they wear, leading to less frequent changes and higher productivity.

Heat Resistance: Excellent heat resistance properties mean that these abrasives are less likely to cause warping or discoloration of the metal workpiece due to overheating.

How can proper sanding techniques improve paint adhesion and finish quality on metal surfaces?

Proper sanding technique is essential for improving paint adhesion and finish quality on metal surfaces because it creates the optimal texture for paint to cling to:

It removes surface contaminants and irregularities, providing a clean and smooth surface that improves paint contact.

Sanding with the right grit size creates micro-abrasions that enhance mechanical adhesion, making the paint stick better and last longer.

Consistent sanding action, achieved using a belt sander with the correct abrasive belts, ensures an even finish that prevents the paint from pooling or sagging.

What maintenance routines are recommended for prolonging the life of belt sanders?

To prolong the life of your belt sander, adhere to these recommended maintenance routines:

Belt Inspection and Replacement: Regularly inspect the abrasive belt for wear and tear; replace it promptly to maintain efficiency and quality of work.

Belt Tracking Adjustments: Check that the belt remains properly aligned and centered during operation to prevent uneven wear or potential safety hazards.

Cleanliness: After each use, clean dust and debris from the sander, especially from vents and moving parts to ensure optimal performance and to reduce overheating.

Lubrication: Periodically lubricate moving parts according to the manufacturer's instructions to reduce friction and wear.

Storage: Store the belt sander in a dry, dust-free environment to prevent corrosion and premature aging of components.

Remember to always consult the user manual for specific maintenance advice for your particular model of belt sander.

What technological advancements in abrasive grain technology can enhance metal finishing processes?

Advancements in abrasive grain technology for metal finishing encompass newer, more durable materials, improved grain blending, and advanced belt designs that promote cooling and longevity. Ceramic alumina belts, in particular, have been tailored to last significantly longer, enhancing productivity and reducing replacement frequency for metalworkers. Additionally, belts engineered with cool-running properties prevent heat buildup that could damage metal surfaces or alter their shapes during intensity-driven sanding tasks. These innovations not only augment finishing quality but also support a safer and more efficient metalworking process.